In Part 1 of this three-part series on business software, Impressions spoke with four companies about the general direction they feel shop operating system technology is going.

Part 2 of the series focused on specific products being offered from each company and the special features contained by each.

In this final installation, each roundtable participant discusses the future of business and shop-management software, hurdles experienced in decorated apparel shops and more.

The roundtable panel includes Preston from Shop Cal, Bruce Ackerman from Printavo, Tom Pawlowski from Impress, and Jay Malanga from Shopworks.

Impressions: Where do you see the industry going in five or 10 years from now?

Preston: It is going to continue to change just as it has over the last several decades —with new decorating methods, improved decorating methods and equipment, and new sales avenues. Today it is social media. In five or 10 years, who knows? But software developers are going to need to adapt as well to the needs of shops as these changes happen. This means not only improving your existing software offerings, but will more than likely mean developing new software applications to fit future needs. Shop Cal software is currently developing a version of Quick Quote design to price specifically the way another branch of the garment decorating industry prices. I am not aware of any other software development company working on a solution for that segment.

Ackerman: It would be incredible if one day you could talk to your phone to operate your business software. “Printavo, can you create a quote for John Doe that’s due next Thursday? He needs 50 more Gildan 2000 shirts,” or “Printavo, what orders do we need to complete today? Can you send them to the production department’s iPad?” This would be very natural and truly amazing.

Pawlowski: Our customers’ needs will likely change moving in the same direction as technology. Our customers demand anytime access to our software and want to be updated on events that are important to them rather than having to check the progress themselves. This expectation is not going unique to the screen printer or embroiderer. Your customers will increase their expectations for real-time access as well. The next generation of labor in the workforce relies on their smartphones, tablets, watches and even glasses to boost their productivity. Offering services to get your clients the information they need to make their business decisions will be the key to your success. Allowing customers to place orders from their own tools and to have their systems notified of important events with their jobs will be important not just to grow your business, but to continue to satisfy your evolving customer accounts.

Malanga: A lot of growth. The demand for embellished products is going to continue to increase and our industry is going to be a direct beneficiary of that. I also think technology will continue to evolve on the production floor as inventors continue to come up with new and interesting ways to get logos onto things. This is the one aspect of our business that really makes it fun — the creative side. This is probably why we are all drawn to it.

Impressions: What’s the biggest hurdle decorated apparel shops face every day? How does your software help with that challenge?

Preston: Again, pricing constantly, accurately and fast. To do otherwise makes a shop look unprofessional or like they do not know what they are doing. Another hurdle is pricing knowing you are not leaving money on the table, and at the same time giving a competitive price. Shops do not need to be second-guessing when giving a price. The “Am I too high?” or “Am I too low?” thoughts end up losing shops money either in lost sales or undercharging. Using software such as Quick Quote helps eliminate that problem.

Ackerman: We think that when a shop is growing, staying on top of everything going on while staying organized is crucial. Printavo allows you to monitor where orders are in your supply chain and perform the necessary tasks to complete them. You can request quote approval, schedule jobs, receive payment, message customers and view all your data in one place.

Pawlowski: Every single one of our customers have done the balancing act between pushing jobs along in pre-production vs. getting the product out of the doors today. Ideally, with a proper system in place, they can focus on their product to improve their process and become more productive. Impress helps automate the workflow so that you can do just that. Once the orders are entered into the system, visibility is given to all departments so that they can work on their parts of the job without having to wait for paperwork to get to them. Checks and balances are also put in place to make sure that your defined requirements are met before Impress queues the job for each department. Utilizing barcode scans, your entire staff contributes to updating the progress of each job in real time, rather than a select few people having to frequently update the rest of your team.

Malanga: In my mind, the biggest challenge is for the small-business owner to commit themselves to being exactly that: a business owner. This is especially true if they want to grow their business. I think a lot of people start a small business as an escape from the “regular” work world and they are doing themselves a disservice in the long run when not committing to the process. If you are going to own a business, embrace being an owner. Things you never thought of, like “systems,” “procedures” and “management,” are going to be the key to your growth. Our software helps with this challenge by giving them a starting point for their company infrastructure. This is not all just for “big business;” these concepts are important for small operations as well. Our software is very configurable for different business types, but once it is set up correctly, it will work whether you do $100,000, in sales volume per year up to $50 million. We have many customers across that sales volume spectrum and they all use the same software.

Impressions: Can you briefly walk the reader through how your software allows a production scheduler to schedule a job on a particular day and time? Is it easy to do and set up? What advantages to you have with this over your competition?

Preston: Quick Quote is designed as a low-cost solution for small shops. During development, I asked a lot of shops what they needed and what they did not really need or would use in a software program. Scheduling was on the very bottom of the list most small shops needed or would even use. The biggest complaint — besides cost — most shops stated about other software they had looked at was that they were too complicated to use. They felt like they would be paying for all these extra features they would never use. In all my years of owning a shop my scheduling system was the next order on the clip board if the shirts were in. Simple. Scheduling is something large multi-auto shops would benefit from more than the mom and pop shops Quick Quote is designed for. All that said, scheduling may get added if enough of my customers want it.

Ackerman: Each invoice in Printavo has a production due date. This is set when the invoice is created and allows the invoice to show up on the production calendar. Users can change the status of an invoice from the calendar and/or drag invoices around to change their due date. It’s dead simple to setup and allows shops to stay on track with what needs to be done.

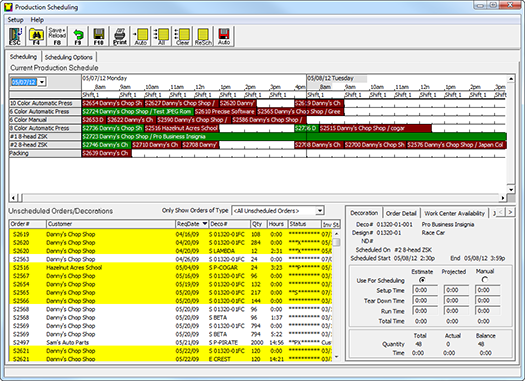

Pawlowski: Production scheduling in Impress is actually available in two different models. Both models are laid out very similar in an intuitive way schedulers and operators alike. The scheduling screen is actually broken down into two different areas – a top and a bottom. The top half of the scheduling screen will display your machines and timeslots that you can schedule jobs to. The bottom half of the screen will display a list of jobs that are available to be scheduled. The list of orders can already be filtered by your requirements to assure that you are only scheduling jobs that are ready to produce. You can filter the available jobs further by selecting the desired order type – perhaps you want to start your day by focusing only on Rush Jobs. You can even sort the available jobs by any of the columns to look at similar jobs. You could then select multiple jobs with the same design and drag-and-drop them all at once to the schedule on the top half of the screen to schedule all of the similar jobs back to back in order to gain efficiencies in your setup times.

Time estimate tables you define can be used so that each job takes up the appropriate time slot on your schedule so that you get a good visual of how time you have available for each machine each day. With a click of the mouse, you can even check out the history to see how long a particular design has taken you to run in the past. Other visuals such as “red” jobs alert you to falling behind schedule. “Yellow” jobs highlight orders with multiple process where some have been scheduled while others have not yet. An example could be if you have an order that has screen print on T-shirts and embroidery on caps, you ideally want to schedule both process together in order to ship the order out complete.

The second mode of scheduling is commonly referred to as the “whiteboard view” because it mimics scheduling in the old days where each job had a magnet with its information on it. You then place the magnets onto the whiteboard to build a queue of jobs for each machine to work on. This mode has the same drag-and-drop interface with all of the features of our advanced mode. The only difference is that you are not interested in estimating the projected run-times down to the minute. You are simply interested in building a queue for each machine, and you rely on the experience of your scheduler to make the call on how many jobs can be done each day.

Both modes are available and can even be used together. We have clients that use the advanced mode to build the schedule with their time estimates. Meanwhile, on the production floor, the Whiteboard view is displayed on large screen TV so that the production staff can see the jobs in their queue at a glance rather than relying on paper reports to tell them which jobs to prep for the rest of the day.

Malanga: Our production scheduling has a philosophy behind it and that is that it is almost impossible for a computer to 100% schedule production because there are so many different variables. In screen printing, for example, not only are you looking for an open spot on a schedule, but you have to consider the number of heads, screen size, flash units available and maybe even who is the crew running a particular press to see if it is appropriate for a job. Our system basically works this way. You set up all your equipment in our system and your production teams. Equipment has properties associated with them, including production rate. We recommend that all new customers set up a “scheduling machine” for each department as a best practice. For example, they would have a press setup in our system called “Schedule Screenprint” that would have average production rates associated with it. When a new job comes in it will automatically be scheduled for the “Scheduling Machine” based on the dates required by the person entering the sales order. You can set up the system to back this off by a few days if you want, and also to avoid weekends, etc.

Procedurally, the production manager on a daily basis sees the jobs that have come in on the Scheduling Machine and moves them to a real machine based on their schedule. A benefit of this is the manager has an opportunity to review every order before scheduling to make sure everything is there. For example, if the salesperson left off a key piece of information, the manager would have the opportunity to put the order on hold and send a message to the salesperson — all from within our system. Everything is documented on the order. This is all procedural and varies exactly in how it is implemented from company to company.

Marshall Atkinson is the chief operating officer of Visual Impressions, Inc., and Ink to the People, Milwaukee, Wis. Atkinson is a frequent contributor to Impressions. He also lectures on sustainability at Imprinted Sportswear Shows (ISS) events, and has participated numerous industry webinar panel discussions and keynote addresses. He serves on the board of directors for the Sustainable Green Printing Partnership (SGP), several SGIA leadership committees, and is a PromoKitchen chef. You can contact him at [email protected], read his blog at atkinsontshirt.com or follow him on Twitter @atkinsontshirt.