Editor’s Note: See the gallery above for some unique, finished designs of which these profiled decorators are most proud.

There’s something unique about the apparel-decorating community. Ask decorators about their counterparts and what epitomizes the good things about the industry and — surprise — they won’t ramble on about themselves. They’ll actually defer praise to others.

The following decorators are all very good at their crafts and they possess some common traits: They are humble; have love for the communities to which they are attached — whether it’s a geographical area or a group of like-minded decorators using water-based ink; curious; set high standards; care about their staffs, vendors and the environment; and last — but not least — they love what they do.

Clearly, the industry’s future is in good hands.

Shawn King

Jakprints,

Cleveland

King is the director of digital direct-to-garment (DTG) printing at Jakprints, regarded by some as masters of the process. Is he the pencil-pushing, hands-off manager type? Quite the opposite; he loves apparel decoration, which is apparent in conversation. And that’s fortunate for the company, as Jakprints is heavily invested in both DTG and hybrid — a combination of DTG and screen printing — machines.

At the young age of 19, King was doing digital sublimation at Jakprints, but soon immersed himself in the all-hands-on-deck efforts the company made to produce DTG designs that looked like screen printing. While other shops were figuring out the print-on-demand (POD) process, Jakprints used the first machines for merchandising work and used DTG printing as an alternative to screen-printed samples. Having dug deep into the DTG raster image processor (RIP), inks and files, King and Jakprints do admirable work, and have achieved their goals of simulating screen printing via this process.

DTG printing often is sold as a solution for those who can’t figure out screen printing because all you do is print a file. Such an approach may work for a photo of a dog that’s printed on a single shirt, but it’s not viable for a popular band, fashion brand or fussy corporate client. King has established himself as a decorator of note because of his curiosity and willingness to experiment, be creative and teach those around him.

Jacob Edwards, owner of Jakprints, says customers don’t really care how decorators put their images on shirts, whether it’s via sublimation, transfers, DTG or screen printing. It’s in such a crazy world that folks like King — who are open to all methods — will succeed.

Nathan Leber

Leber Design & Print,

Grove City, Ohio

After being raised on a farm, Leber’s strengths include figuring out how anything works, dealing with adversity, solving problems and being resourceful to get things done. These also are characteristics of a good decorator.

He went to art school and graduated as the recession gripped the economy in 2009. Simply needing a job, Leber applied for a position at a print shop. He started at the most fundamental level — reclaiming screens. In the following years, he learned manual screen printing, sampling, relabeling, packaging and more. Eventually, he oversaw everything but sales, and the shop was producing more than 1 million shirts per year.

He started doing after-hours printing experiments, eventually realizing he would need to open his own shop to achieve his true goals. So he started Leber Design & Print in a small space, performing customer-service, art, printing tasks — you name it — with just a couple of part-time helpers. Being in control allows Leber to be artist-friendly, use environmentally friendly methods and, most importantly, help people in the community, which is his favorite part of the job.

“There is something about printing that still excites me,” he says about why he likes his craft. “The tactile nature of it — the great feeling of when the ink lays down perfectly. There is something so awesome about that manual process of creation. I still get excited about it.”

As many shop owners dream of growing their businesses to accommodate as many automatic screen-printing presses as possible, Leber has no such ambitions. Rather, he plans on staying small, perfecting his craft and doing what he likes.

Erin Moore

Barrel Maker Printing,

Chicago

Not only might she be one of the better printers around, but Moore also is one of the friendliest. She’s modest about her expertise and accomplishments, but her shop features plenty of good work and is a large production facility that, under her management, is humming along.

Moore didn’t learn the screen-printing trade in school. Rather, she started her journey into apparel decorating with a Speedball screen-printing kit from a hobby store. She and her husband, Justin, used it to make shirts for their kids. Eventually, he bought a manual press and set it up in their living room. As he gained sales, she realized it was up to her to print orders, which included lots of trial and error.

Always humble, Moore admits part of being successful is learning from mistakes. Clearly, it works because her shop prints on all kinds of difficult substrates, and also uses mostly water-based ink.

Moore says she loves printing and tries to make time once a month to intensely focus on honing her craft. She revels in the efficiency of laying ink down and creating something with her own hands, and she’s proud that her journey has led her from knowing nothing about decorating, to now being able to crank out good-looking shirts.

Dominic Rosacci

Superior Ink Printing,

Denver

Rosacci has been screen printing since high school — 12 years and counting — and he still loves it. Running one of the more eco-friendly shops in the country, he probably is the most aware of what isn’t green in his shop and our industry, at large. He knows his business is far from perfect but has the drive to continuously improve it.

Rosacci is driven by his ambition to be ethical in his printing methods and sourcing practices. “Inspiration fuels creation,” he says, noting that pushing forward on the ethical front attracts good employees who care about the business which, in turn, attracts dedicated customers.

Like many young printers, he started as a snowboard and skateboard enthusiast. He established his own brand, Neovolt, and contracted out the printing, but was driven to learn more about the process. Rosacci eventually started his own shop in 2010.

He never wants to stand still and can be found experimenting with discharge bases and plastisol top prints. One of his favorite projects is Allmade, which manufactures T-shirts that are ethically produced by workers making a living wage in Haiti. Rosacci says the initiative is pushing the industry toward more ethical production, which stokes his motivation.

Stephen Till

ASPS (A Small Print Shop),

Denver

In 2004, Till decided to stop touring with bands. Needing a creative outlet that he could pursue from home, he got a kit and started printing shirts in his basement. He went through many years of intense trial and error, often quitting after failures, then getting drawn back in after thinking about ways to overcome the challenges.

Till eventually got better and pushed through moments of lamentation, he admits. The experience forged someone who now loves what he does.

His “small” shop features two automatic screen-printing presses, and he invests in technology and systems to crank out orders with a small staff. Till may be more into technology than some printers, but he realizes he is in the vanguard of an industry that sees direct-to-screen (DTS) technology in small shops and investments in software for customer service and scheduling.

“I love printing, particularly hands-on [printing],” Till says. “There’s something so satisfying about it.”

In the past 18 months, he has been focused on making beautiful presentations so that not only do customers know what they’re getting, but he also can sell them on making better shirts. He also has successfully experimented with multiple printing techniques, including discharge underbases (for softness) paired with plastisol overprints (for color brightness and accuracy.)

Brandon Lennert

Inferno Screen Printing,

Kenner, La.

Thirteen years ago, Lennert was living in Seattle and had keen interests in art and music. He only became attracted to screen printing because some of his friends worked at a shop. Like many good printers, he started with the basics: reclaiming screens. Then, he started operating manual screen-printing presses, eventually displaying the aptitude required to manage the shop at which he worked.

Clients started buying more and more shirts, mostly from popular bands, and Lennert grew frustrated that he couldn’t crank out large orders as quickly or easily as shops that had automatic presses. So, he eventually left the shop, bought an automatic press and was off to the races at the helm of his own screen-printing business.

Lennert, like most good printers, believes in not overcomplicating things; is always curious and humble; and continuously strives to get better at his craft. He prints mostly using water-based ink and he always goes the extra mile to make a print better. Lennert knows the ultimate goal of owning a business is to make money, but he often adds another screen, mixes one more color or does whatever it takes to make an ordinary print extraordinary.

Customers get the best shirt possible “whether they know it or not,” he says, with a laugh. He figures that any shirt’s extra “coolness” will result in more sales, thus customers will be better off and the ultimate benefit will be when they return for more shirts or tell their friends.

Lennert always is trying to improve his methods with continuous R&D. New products, like HSA inks, intrigue him, so he experiments with them appropriately. He also is doing more cut-and-sew work.

“I love printing, and though I do my business work, I would rather reclaim screens than do the books,” Lennert says.

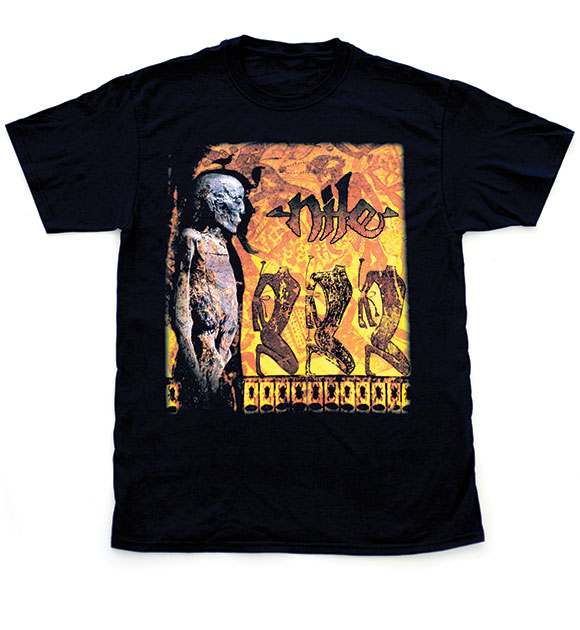

Check out the promotional video above that Lennert’s shop did with the metal band, Goatwhore.

Eric and Val Solomon

Night Owls,

Houston

Eric Solomon started his apparel-decorating journey in his garage with the ever-popular Speedball screen-printing kit, printing shirts for friends. He also took a part-time job cleaning screens at a local shop. After a year, he was a full-time employee.

He would “freak out a bit” at big jobs that came his way, but he always figured out how to get them done. In 2010, he started Night Owls, which initially was only offered screen-printed shirts; now, the merchandising company offers and sources all kinds of products. The company is known for its work with water-based inks, including high-solids acrylics (HSA).

Much trial and error has gone into Night Owls perfecting its craft. Eric Solomon gravitated toward the printing aspect of the business, while his wife, Val Solomon, has gravitated toward the art — but they both do it all. To get better, they continuously ask questions to their vendors and other printers (and I can attest to that being a two-way street and they are generous with their information.)

A recent achievement has been printing simulated-process jobs with water-based, HSA inks. Keeping the ink flowing, dealing with the way ink pigments darken over time, and discovering how the inks mix have been challenging but rewarding breakthroughs. The husband-and-wife team has spent hours upon hours re-doing jobs until they are correct. This has improved their printing, in general, and they are getting phenomenal results.

The future goal is to grow the company, even though they struggle with the personnel issues that come with such growth and the time commitment required. Despite those pressures, Eric Solomon still can be found at the screen-printing press.

He was asked if he still liked printing after spending time setting up a 10-color simulated-process print using HSA inks. His reply: “Yes, I still get very excited about it.”

Rick Roth is the owner of Mirror Image, a company known for decorating innovation, promotion of charitable work and ethical standards. He is the publisher of inkkitchen.com, a social-media company that provides free information on apparel decoration. He also hosts Shop Talk sessions at the Imprinted Sportswear Shows. For more information or to comment on this article, email Rick at [email protected].