It only takes one visit to a retail clothing store to see the numerous varied clothing items available for purchase that have a printed image located somewhere on each garment. Much of today’s imprinted apparel generally is aligned with the tried-and-true leisurewear market, but an increasing amount of today’s selections are trending toward gym, workout and compression apparel. Printed images are even being seen with creative fashion garments, which is an exciting and new addition to high-profile imprinted clothing.

There also has been a significant increase recently for the boutique business, where selling fashionable unique clothes and specialized wearables with brilliantly printed images has created a new lease on life for many new and classic styled garments. Here, you can find an unbelievable array of graphic styles and finishes that propels the urban, street and nouveau clothing markets — as well as garment decoration — to new heights as it recognizes a distinct and valuable purpose. Wearers of these apparel styles can demonstrate their individuality and set themselves apart from the ordinary.

Regardless of the garment concept and market direction, the wearable graphic’s importance and its integral combination with the garment construction is crucial for the sale of the item. And, as with any art form and wearable style, the relentless search for new concepts and innovation is as strong as ever. For textile imaging, technology has yielded heat transfers that complement many garment styles.

Transfer Advantages

The heat-transfer inks’ ability to be printed on a substrate paper or film surface and stored as a stock item has obvious advantages in a fast-track business environment. The transfer can be taken from storage and immediately heat applied to a blank garment, thereby significantly shortening the time from order placement to delivery in the marketplace.

Printing heat transfers onto a carrier substrate paper or film also can be advantageous compared to printing wet inks onto a finished garment. Without care and attention, the latter can lead to damaged and unusable products during the application process.

Also, stock transfers can be applied to multiple garments quickly to meet demands for fast turnaround. As a bonus, the heat-application process is easy to learn and can easily be repeated to produce a perfect transfer every time.

Heat-transfer inks have been available for quite some time, but most have seen an array of technical additions in recent years, making them more efficient and easier to apply to multiple substrate surfaces.

Moreover, most of these inks are aligned with a qualified and repeatable color-matching system that includes spot colors, four-color process and fluorescent inks aligned with a qualified color formula guide. This is the best way to determine multiple and repeatable color values.

What’s Available?

Durable heat transfers also now are available for multiple styles of industrial workwear, in which wash and stretch durability is in demand.

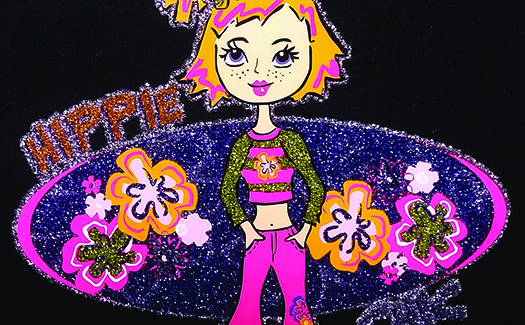

Special effects and textured finishes also are well suited for heat-transfer application. Numerous fabric-textured faux surfaces can produce superb graphics once applied to the garment and combined with an ink or image finish that brings out their textured qualities.

Shiny heat-transfer finishes such as glitter, shimmer, metallic and pearlescent still maintain a significant place in the heat-transfer world, where their distinct qualities remain in demand.

For heat-transfer preparation and print application, the ink does not come first. Instead, the paper or film substrate to which the ink is applied receives primary consideration. With many variables regarding the ink and heat application of the transfer to a garment, the paper, film or any other medium can change the appearance and visual value of the transfer ink once applied to the garment.

With so many technical advances in the production and application of heat-transfer ink and additives, as well as the onward march of digital transfers, there is no doubt that the heat-fusible market will continue to reach new heights in the not-too-distant future.

Chris Pluck, business development director for Insta Graphic Systems, has been in the imprinted textile industry for more than 30 years. He has a background in screen printing and offset lithography technologies, and was instrumental in establishing inventive heat-fusible printing products and print application methods. For more information, visit instagraph.com.