A seemingly never-ending stream of technical advances is fast propelling this cutting-edge apparel decorating technique into the mainstream

In Part 1 of this two-part series on the growing importance of direct-to-film (DTF) printing, we looked at how DTF works and the issues involved in handling larger print orders. In Part 2 we look at some of the advances being made in the area of DTF special effects and purchasing options/decisions.

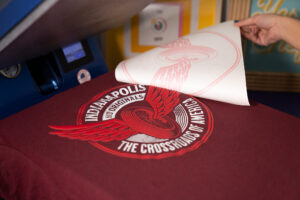

Today’s DTF transfers, like this Ninja Transfers example, are softer, stretchier and more durable than ever. Photo courtesy of Ninja Transfers

Arguably, beyond the issues related to larger print orders, as discussed in Part 1, the other leading concern when it comes to DTF decorating is the “feel” associated with it compared to a well-executed screen-print or sublimation image. The reason for this is the fact that, in contrast to sublimation or screen-printing (in which the ink is absorbed into the weave of the fabric on which it is being placed), a DTF image sits atop the fabric, so to speak. The result can be a kind of “plastic” feel and compromised breathability, especially if the design in question is a large one.

That said, while there’s no denying DTF decoration cannot yet quite match the feel of those other decorating methods, the effect can be successfully mitigated through things like savvy design and pressing twice instead of just once. Specifically, by including plenty of open areas, or “air spaces,” in your design, you can lessen the “plastic-ness” and breathability issues that afflict larger, less carefully crafted images.

The DTF transfers now being produced by such top-quality custom DTF providers as Ninja Transfers, STAHLS’ Transfer Express and 613 Originals also feature a much better feel, or hand, than in years past, to the point where such issues are fast becoming almost nonexistent.

Complementing the problem of feel is the issue of durability and the fact that low-quality DTF prints, in particular, have had a tendency to not hold up over the course of repeated washings. The good news here is that, as is the case with feel, a well-made transfer these days is more than capable of standing up to literally scores of repeat washings. Again, this is especially the case if the transfers you’re working with are being sourced through a reputable custom transfer provider.

Companies like 613 Originals are making available an ever-widening variety of special effects options, including puff and glitter. Photo courtesy of 613 Originals

“It’s been amazing to see how much softer DTF has gotten over time,” said Michael “Ninja Mike,” Nemeroff, CEO of custom DTF provider Ninja Transfers, describing the industry’s advances in this area. “They are also durable and stretchy at the same time, which is great to see. We’ve worked on over 100 combinations of the most optimal film, ink and TPU powder [i.e., the adhesive powder that allows a design to adhere to its substrate] to create a product that is soft, matte finish and durable up to 100-plus washes when line dried and 60-plus washes when put in a dryer.”

Along these same lines, Dave Conner content director at custom DTF provider STAHLS’ Transfer Express, said his company employs a “proprietary supply chain of inks and carriers for superior color consistency and print finish,” built to avoid inconsistent supply-chain issues and improve hand feel. “We are continually innovating to provide our customers with the most technologically advanced transfers,” Conner said of the company’s efforts to create its brand of transfers.

“Advances in inks and powder have made transfers feel softer and more integrated with the fabric,” agreed Nate Sprowell, vice-president of custom DTF printing at 613 Originals. “While DTF doesn’t yet match the feel of something like discharge screen printing quite yet, the gap is closing fast.”

Special Effects and DTF Adhesive Powder Issues

Historically, another couple of limitations, as it were, associated with DTF have been 1) the inability to incorporate special effects—think glitter and puff designs, or the highly specific colors associated with sports teams and other trademarked organizations, and 2) the mess that can result from working with DTF’s requisite adhesive powder.

A fresh batch of transfers as produced by an Epson hybrid DTG-DTF printer. Photo courtesy of Epson

With respect to concern No. 1, not much you can do here if you’re creating your transfers in-house with a smaller, less advanced machine. However, this is yet another area in which the situation is changing rapidly, with the various top-end custom DTF providers out there increasingly providing design types and color matching capabilities that would have been inconceivable in years past. The aforementioned top-end manufacturers 613 Originals, Ninja Transfers and STAHLS’ Transfer Express, for example, all include a number of special effects choices among their many product offerings.

“At 613 Originals, we offer popular options like puff, metallic, and neon transfers – even Full Color CMYK glow-in-the-dark…DTF is pushing innovation across the board, and we’re excited to see what’s next,” Sprowell said.

Similarly, Ninja Transfer’s Nemeroff noted how his company has introduced a number of new films, like glitter and glow-in-the dark. “We have also recently rolled out Gold Foil, Silver Foil, Copper Foil and other film types,” Nemeroff said.

Something else to bear in mind: for those decorators familiar with heat-pressing, each and every one of the DTF transfer suppliers mentioned also provide a variety of non-DTF options, ranging from screen-printed transfers to custom patches that create the same look as conventional machine embroidery.

While higher output DTF printers, like this M&R Quatro model, don’t come cheap, for those shops already doing a fair amount of DTF decorating, they can make all the difference in the world. Photo courtesy of M&R

“Use a reputable supplier offering DTF as a service and also remember that there is a world beyond DTF,” STAHLS’ CEO Carleen Gray said. “DTF has become synonymous with the word transfers. [But] it’s important for people new to the business to understand there are many types of transfers, and DTF is not a one-size-fits-all, even though much of the advertising in the space would have you believe they are the best choice for every print job. I would caution new users to do their research and choose the best decoration technology for the job.”

Bottom line, heat-press decorators looking to offer something special no longer need to go to screen printing to do so—and there will undoubtedly only be that many more options to go with as time goes on.

With the respect to concern No. 2, this is yet another area in which the DTF equipment manufacturers of the world are quickly solving the problem through the creation of standalone and/or fully automated adhesive application systems that are specifically configured to prevent an undue quantity of particulate matter getting into the air and possibly endangering operators.

Examples of the former include the Vastex PTF-100 DTF powder application system and Equipment Zone’s EZ-JET PRO 32, which includes a dryer component as well.

As for the latter, this category encompasses pretty much every industrial grade DTF printer on the market these days, from such high-output DTF systems as the M&R Quatro to the higher-output models comprising the ColDesi, Brother and Roland lines, among others.

Direct-to-Film Printer Cost and DTF Outsourcing

Which brings us to the question of cost. Even a basic commercial-grade DTF printer will cost you a good $5,000 to $7,000 or more. As a kind of bonus, many of today’s smaller-size models can be used for director-to-garment, or DTG, decoration as well. Nonetheless, this represents a pretty hefty outlay of cash, especially for those smaller shops that are merely DTF curious. Examples, of these kinds of machines include the Brother DTX Pro, DTF Prestige R2 desktop printer and the Epson SureColor F1070.

Meanwhile, moving up a notch or two to one of the many larger-scale industrial-style machines out there, complete with automatic roll-to-roll transfer material-feed and fully integrated adhesive spreading and curing, can run you $20,000, $30,000 or more—a lot more in some cases.

Ninja Transfers’ new 30-foot gang sheet option is one of a host of options introduced in recent months by the custom DTF transfers industry. Photo courtesy of Ninja Transfers

Note, when it comes to more industrial-style systems, there is a wide range of machines out there offering a similarly wide range of output rates. Machines occupying the larger, more expensive portion of the space, for example, include the M&R Quatro, Brother GTXpro R2R DTF System, DTF Station Prestige XL4, Epson SureColor G6070 and ColDesi DigitalHeat FX DTF-24H4.

Other smaller, less expensive systems include the ColDesi DTF 12H2 Basic and diminutive tabletop Roland VersaSTUDIO BY-20, which goes for around $8,000 and can be integrated with its own DTF powder shaker and heater unit in the interest of creating a fully automated system. No matter what size system you go with, it’s important to bear in mind a DTF printer requires a fair bit of maintenance to ensure it continues working properly. At issue here are the print nozzles, especially, which can become compromised or clogged by the ink the systems employ.

Nonetheless, despite the upfront costs and added work these kinds of systems engender, there are still plenty of reasons to take the plunge: especially if your business is an established one, with plenty of customers and orders in need of fast, effective fulfillment.

Reputable, well-established companies, like STAHLS’ Transfer Express, employ the materials and methods required to ensure their transfers are of the highest quality. Photo courtesy of STAHLS’ Transfer Express

“If you are screen printing already and outsourcing transfers, it’s time to invest in a direct-to-film printer. The benefits of outsourcing are only short-lived for a screen-print shop. The lower cost per print, increased flexibility and ease of use are great reasons to bring a printer in house,” ColDesi’s director of marketing, Marc Vila said.

As an added benefit, Vila noted that in addition to the DTF decorating a shop might be doing at present, you will likely “find more jobs to run through the DTF printer as you get used to the process” as well.

As for those decorators who are already creating their own DTF transfers but looking to grow this aspect of their business through the possible acquisition of an even larger system, Vila said, “This is going to really depend on production. A small printer like the BY-20 is going to be great for very short runs that don’t require a fully automated process of powder application and curing.”

Beyond that, Vila noted that by going with a larger system, “You will find the consistency in quality vastly improves with a more automated system. The answer is really in the math. How many prints are you running a day? How many hours do you spend running a smaller machine? If you increased production speed 10, how would that impact your business?”

In this same vein, Brian Richards, marketing director at ROQ, which recently introduced what it calls its IMPRESS automated heat-press system, said his company is seeing interest in DTF among decorators of all types and sizes.

A closeup view of a ROQ FEED transfer-placement module working in concert with a ROQ IMPRESS automatic DTF decorating system. Photo courtesy of ROQ.US

By way of analogy, ROQ’s Richards said, “A growing small business that started with DTF on one heat press [often] views the IMPRESS today much like a screen-printing business that started with a manual press views upgrading to an automatic screen-printing press. Once the business scales to enough volume that you are hiring more labor to keep up, automation begins to make more and more sense…We’ve also seen some midsize decorators adopt DTF to move a percentage of their screen printing to DTF and maintain only their highest volume orders for automated screen printing.”

“Some will use DTF as a complete business model, where others will use it to take pressure off their other decoration methods,” agreed Zac Biberstine, director of product management at M&R said. “We see DTF finding its place amongst large traditional screen-printing operations, where it’s adding efficiencies, opening opportunities, and taking pressure off things like cost and timeline. We also see DTF finding its place as entry level equipment for those that are brand new to garment decoration.”

Whatever the case, if and when a company decides to bring its DTG printing in-house, it pays to 1) go with a top-quality system—and top-quality materials—as opposed to a cut-rate no-name printer from abroad and 2) as mentioned earlier, be ready and willing to put in the necessary work to keep the system running smoothly.

“While there are a lot of low-cost options for DTF printers available from overseas right now, I fully believe that having U.S. support from a partner who you know and trust is invaluable,” said ROQ’s Richards.

“Not all ink, film and adhesive is the same,” agreed ColDesi’s Vila. “We have tested dozens if not hundreds of various combinations, and it’s not the same. From time to time someone will say, ‘You can get the same thing from XYZ, [but] it’s just not true. This is true with everything else in our industry too, right? Not all cotton shirts feel the same. Not all vinyl feels the same. Not all cutters work the same. Not all heat presses are equal. The same is true for DTF printers and supplies. The ink, film, powder, printer and dryer are all a system that involves electrical, mechanical and chemical engineering.”

Along these same lines, with respect to the importance of having an equipment and materials supplier you can count on, Vila noted. “You will find various challenges with running a digital printer, like matching colors. Having industry experts to help you with these challenges is huge. If you don’t have support, you will spend hours chasing problems. These machines work hard, and can run heavy production, but just like everything else, you need expertise.”

Similarly, when it comes to maintenance, M&R’s Biberstine emphasized, “Although basic machine operation and maintenance isn’t difficult, we find that preparing our customers with a two-day in-person training class, sets them up to be successful and gives them all the tools they need. There will always be advanced options for customers to dive deeper, create their own profiles, or push the boundaries of this evolving technology. But the learning curve is quick, and most customers are up and running their own graphics on the first day after install. This is one of the main reasons DTF has been so popular. It’s easy to staff and easy to get going quickly.”

“Training and maintenance are very important for DTF. We hear frequent stories about users buying machines will little-to-no training and regretting the decision,” Vila agreed. “The thing to consider is that these machines automate [multiple] processes. Printing, adhesion application and curing. This is a reasonably complex system. If you know how to operate and maintain it, it’s easy. If you don’t understand proper operation, you can end up with a mess.”

Outsourcing, Custom DTF Transfer Providers

Meanwhile, as discussed earlier, for those looking to test the waters without having to spend a whole lot of cash, there are any number of custom DTF providers out there who would like nothing more than to provide you will all the transfers you could ever need. Better still, the industry’s leading custom transfer providers are currently going at it hammer and tongs to carve out as much market share as possible, offering everything from better and better transfers to ever more competitive pricing and faster-than-ever turnaround and shipping times.

Over the course of just the past few months, for example, STAHLS’, Ninja Transfers and 613 Originals have all debuted everything from the aforementioned ultra-soft transfers to transfers that can be peeled hot or cold; a range of different online design services and platforms; the aforementioned specific effects options; faster and faster turnaround times; ever bigger and better sheet-ganging options, including a 30-foot-long gang sheet option from Ninja Transfers; and even transfers that can be pulled apart by hand (as opposed to being cut apart with a pair of scissors) from STAHLS’.

The result is not only a situation in which pretty much anyone with access to a commercial-grade heat press can give DTF a try, but the option of creating a substantial business out of DTF decoration—whether you’re just starting out or interested in broadening an existing company’s decorating options. And, of course, if/when you reach the point where the numbers of orders you are receiving is such it’s beginning to make sense to maybe bring some or all of your transfer production in-house, all the better!

Ed Note: To see Part 1 of this two-part series, which focuses on the basics of DTF apparel decorating and the equipment employed to manage larger production runs, click here. Updated 4/24/25