There are many new fabrics on the market today that incorporate both polyester and Lycra spandex. Printing on these fabrics can be a challenge, so here are a couple of tips:

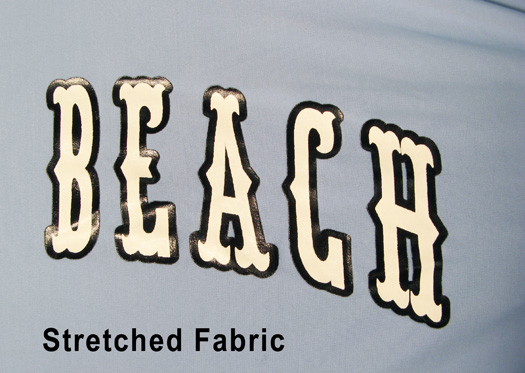

1. Plastisol inks are usually stretchy by nature, but adding a little bit of stretch additive can greatly improve the stretchability, especially for performance and athletic fabrics, which often contain a high percentage of Lycra spandex. Adding excessive amounts of a stretch additive, however, could reduce the opacity of the ink, so it is important to add only about 1%-5%.

2. There also are new inks on the market, such as International Coatings’ 7100 Performance Pro, which have been specifically formulated for these next-generation performance fabrics. These inks have great stretchability and allow for lower curing temperatures (275°F). The ability to cure at lower temperatures helps to control any potential dye migration issues.

Kieth Stevens is the Western regional sales manager for International Coatings. He has been teaching screen printing for more than 10 years and is a regular contributor to International Coatings’ blogs. For more ink tips and information, visit iccink.com and read the company’s blog at internationalcoatingsblog.com.