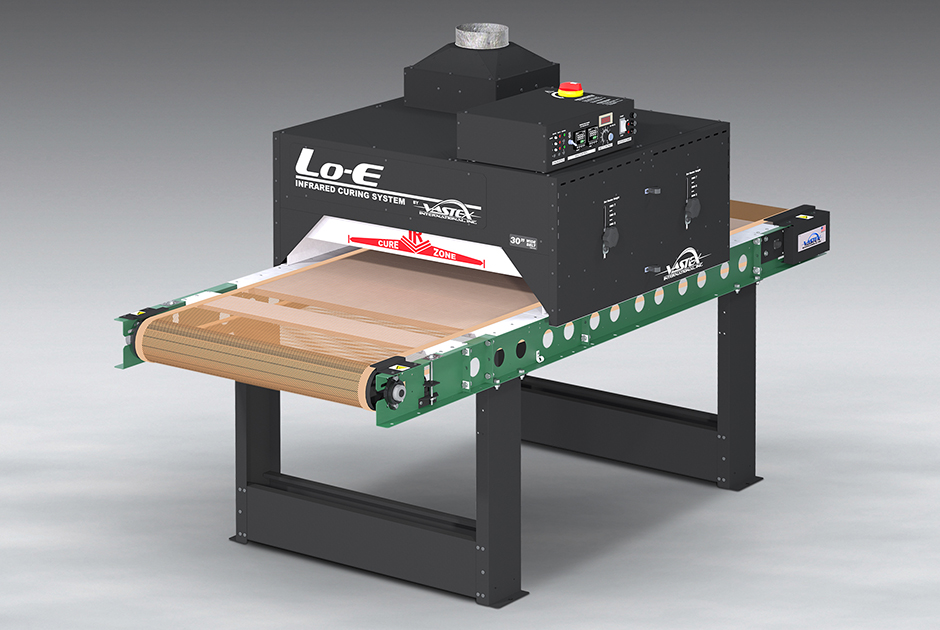

Vastex Intl., Bethlehem, Pa., has debuted a new Lo-E Dryer which cures DTG-printed inks and pretreatment, and water-based screen-printed inks and discharge, at high rates using 20% less energy than comparable dryers.

“We engineered the Lo-E for printers who have limited amperage, and those who simply want to cut energy costs and carbon emissions,” says Mark Vasilantone, president of Vastex International.

The dryer cures up to 45 garments/hr. printed with digital white ink at a three-minute dwell time, according to the company.

Modularity permits users to quickly add one or multiple heating chambers and extend the conveyor belt, multiplying capacity in direct proportion to each heating chamber added. Conveyor extensions can also be added to the front or back of the dryer.

Drawing only 22 amps, the dryer’s two 24″ x 18″ high-efficiency infrared heaters provide 4600 watts of power.

A 370 CFM exhaust system evacuates moisture and air contaminates from the heating chamber and cools the enclosure’s outer skin and control panel. The 30″ x 88″ long conveyor runs true by means of a low friction belt aligner patented by the company.

“Although the Lo-E Dryer is designed for curing of DTG garments, it can also cure screen-printed water-based inks and discharge,” Vasilantone says. “It’s the most energy efficient dryer in our lineup, and maybe the world.” — D.S.