Knowing when to upgrade your production processes is critical for any commercial apparel decorator looking to grow their company

You didn’t start your shop because you love chasing approvals or spending weekends reclaiming screens. You’re here to build something real. You want to grow sales, get more customers and do work you’re proud to put your name on.

If you find yourself in a situation where you’re constantly playing catch-up or always stuck in the same old workflow, you can’t afford to wait around anymore. The right automation, whether it’s an auto press, a better heat press setup or production software, can free up your time, improve consistency and help you scale without burning out.

So how do you know when it’s time to invest? Let’s break it down.

When is it Time to Upgrade your Production Processes?

Ever feel like your press is running you instead of the other way around? You walk in on Monday morning, and you’re already behind. The manual press is loaded, the clock is ticking and the orders just keep piling up. That’s when the thought creeps in. Maybe it’s time for an upgrade.

So, how do you know for sure it will work out? Start by asking yourself a few simple questions:

- Are you turning away work because you cannot keep up?

- Are you constantly exhausted because you’re printing past midnight a few days a week?

- Are jobs getting delayed or rushed out the door? Is quality slipping?

If the answer is, yes, to any of these, your equipment may be creating a bottleneck.

To help you make up your mind whether to invest in a new piece of equipment or not, imagine what you’ll be able to do with the time savings. Photo by ismailbasdas – stock.adobe.com

Adding an auto press or a more advanced heat press setup can lighten the load and let you do more in the same amount of time. That means more opportunities for sales calls, quoting and building customer relationships—you know, the stuff that actually grows your business.

Look at your numbers. Track how many shirts you print per hour and how long it takes to set up each job. Compare that to what an automated setup could produce. In many cases, shops find they can double their output or cut labor time in half with the right upgrade.

Something to keep in mind: doing so is not about chasing fancy equipment. It’s about knowing when your current setup is holding you back, like dragging an anchor behind you.

Granted, staying manual might seem like the safer move, but it could also be the most expensive decision you make this year as well. How you use your time matters.

Measurement and Goal Setting for Your Company

Before you invest in new equipment, though, you need to understand what your shop is currently capable of. That means measuring how your business is performing. You can’t improve something you’re not tracking, nor can you justify an upgrade without knowing the numbers.

Let’s start with two critical metrics: ideal daily output and cost per impression.

- Your ideal daily output is the number of prints or jobs your shop should be able to complete in a normal day without rushing or cutting corners.

- Cost per impression is the total cost to produce one print, including labor, materials, overhead and waste. Knowing this number will help you understand your pricing and your profit margins.

Now, let’s add in some other key performance indicators (KPI) to further guide your decision making, including:

- Capacity – how much work your shop can handle at full load.

- Velocity – how fast your shop can move jobs through each stage of production.

- Value per hour – the total revenue from a single piece of equipment divided by its use hours.

- Error rates and downtime – pretty self-explanatory, but no less critical in that they show where money and time are leaking from your process.

In order to make an informed investment decision, it’s crucial you determine how your shop is performing with what you already have. Photo by Wasana – stock.adobe.com

Are you tracking this stuff? Here is a simple example. A manual shop might run one press and complete 200 shirts in a day with a single operator. An auto shop might print 2,500 shirts in the same amount of time but with three people working on it.

This represents a 12-fold increase in output, with better consistency and fewer physical demands on your team. Sure, your labor costs increased as two more people were added to the crew. But the financial gain was so much greater it almost doesn’t matter.

Shops that measure consistently know exactly when they hit the ceiling with respect to their existing production capital. They can plan with confidence because the data tells the story. If you’re guessing, you’re gambling. If you’re measuring, you’re managing. The trouble is too few people do the math.

Types of Automation Upgrades for Apparel Decorators

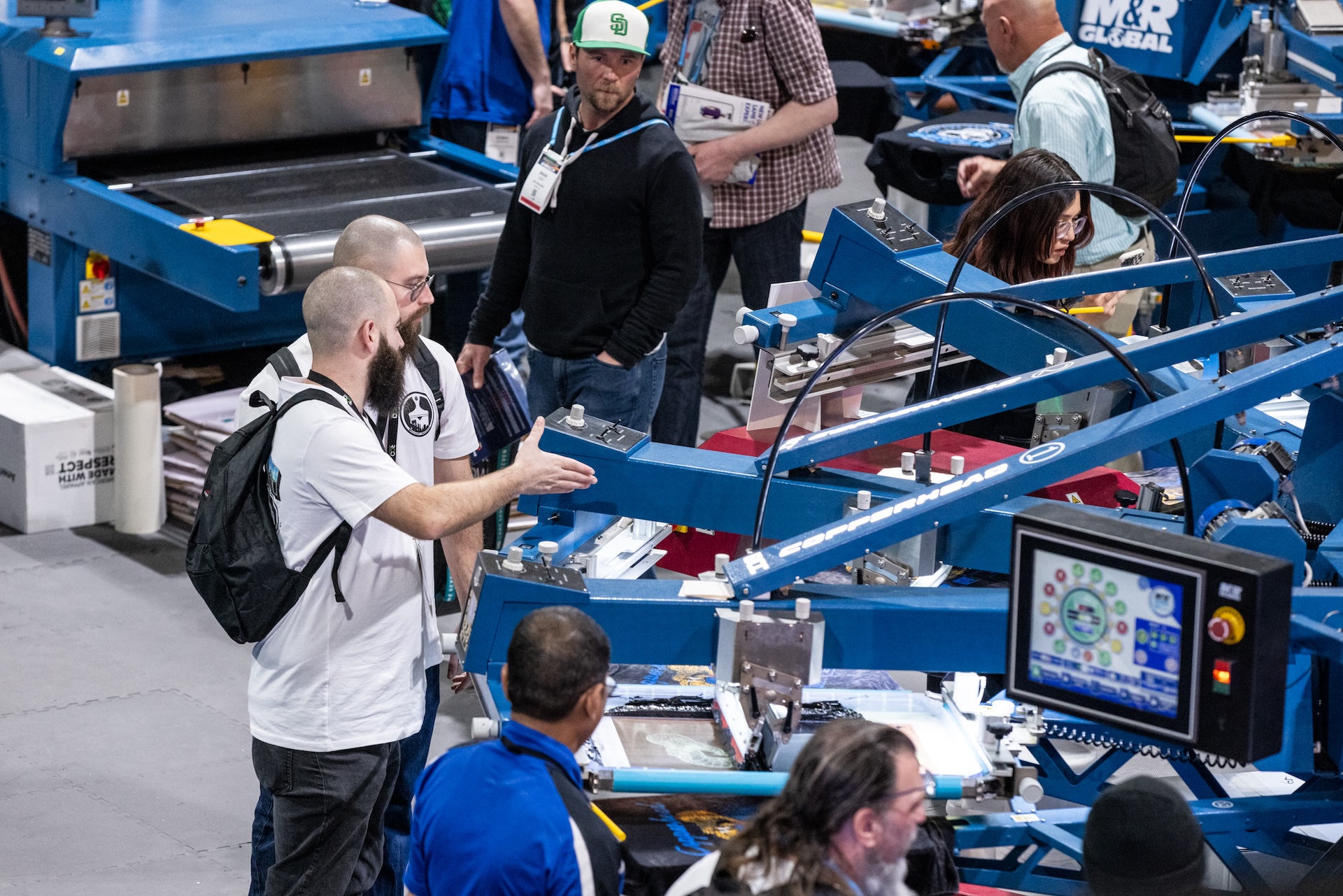

When screen printers think about automation, their first thought is usually an auto press—and for good reason. Moving from a manual to an auto can dramatically increase your daily output and reduce labor strain.

That said, doing so is not always the smartest first move. Sometimes, improving the front end of your production processes can have an even bigger impact. Tools like a computer-to-screen (CTS) exposure unit or an automatic screen coater don’t just save time, they drive repeatable quality into your screens, which in turn has an impact on every job that comes in their wake.

Don’t forget the front end of your company’s production processes: case in point, consider how installing a direct laser image exposure unit, like this Saati system, would affect your shop’s screen prep. Photo courtesy of Impressions Expo

Consider the ripple effect. If your screens are coated consistently and exposed accurately every time, your setups are faster, your registration is tighter and your print quality is more predictable. That leads to fewer mistakes, less spoilage, quicker approvals and, by extension, repeat business.

Investing in these areas also helps stabilize your overall workflow, making later upgrades, like an auto press, that much more effective. Think of it as building a foundation before you add the upper floors.

Other smart automation options include reclaim units that speed up screen cleaning, production scheduling software to help manage orders in real time, conveyor dryers with programmable controls for better curing consistency or barcode scanners at each press to track jobs and help reduce manual input errors.

Bear in mind, you don’t have to automate everything all at once. Start with those areas where your bottlenecks occur most often. The best upgrades fix real problems, as opposed to just looking impressive on a shop tour.

“Shiny object syndrome” doesn’t necessarily equate to more profitability.

Pitfalls When Implementing Automation in Your Shop

Automation sounds exciting until it starts collecting dust. One of the most common mistakes is buying more of it than you really need. A feature-packed system might look impressive, but if you only use a fraction of what it’s offering, you’re merely paying for complexity.

Worse yet, introducing a bunch of all-new tech into an already disorganized workplace is like pouring gas on a fire. If your current processes are clunky or unclear, software will not fix that. It will just help you make bad decisions and mistakes that much faster.

The other trap is thinking automation runs itself. It does not. Tools take time to learn. People need time to adjust. If ownership is not hands-on in terms of the way the process is run, the team ends up flying blind.

If you want automation to achieve the best results, you have to understand it entirely. Otherwise, you’re just throwing money at a problem and hoping it solves itself. Smart automation is not just about speed. It’s about control, clarity and building a shop that runs better all around.

As my friend Richard Greaves likes to say, “What problem are you trying to solve?”

Workflow Tech That Actually Works

If you are still running your shop out of an email inbox and a stack of scribbled notes, there is a better way.

Today’s shop management platforms are built to streamline the mess. We’re talking online stores, faster order intake, instant approvals, automated artwork, production schedules that make sense, and real-time shipping and inventory updates. All in one place.

That is the power of a solid workflow system.

Each platform has its strengths. Printavo (printavo.com) is an industry favorite thanks to its clean interface, built-in team chat and visual job board, which helps keep everyone on the same page. Similarly, DecoNetwork (deconetwork.com) shines if you build online stores at scale and need back-end production tools to keep orders moving, while STAHLS’ new FulFill Engine (stahls.com/fulfill-engine) is geared toward direct-to-film (DTF) and e-commerce fulfillment, especially for creators selling lots of custom designs. For its part, Chipply (chipply.com) makes fundraising and school store setups fast and simple, while YoPrint (yoprint.com) offers fast quoting, production calendars and customer portals. Finally, PriceIt (priceitsoftware.com) brings powerful customization with deep production tracking.

No matter the platform, the goal is the same: fewer mistakes, faster turnarounds and less time chasing down info.

That said, not every shop finds the perfect fit right out of the box. One of the biggest hangups for owners who have not yet adopted a system is the search for something that works exactly the way they do. The fact of the matter is most industry software is built to cover how most people run their shop, not each and every one of us.

If your workflow is super unique or involves custom steps, you might never find an all-in-one solution that feels right. That is why some business owners decide to build their own system or use tools like Monday.com (monday.com), Airtable (airtable.com) or Trello (trello.com), options that offer flexibility but come with more setup work. Either way, the goal is to get the chaos out of your head and into a system everyone can follow.

Costs vs. ROI When Upgrading a Decorating Apparel Shop’s Processes

When it comes to software, most shop owners want to know one thing. How much is this going to cost?

Most platforms start out at around $100 to $250 a month, depending on the tier and features. Printavo starts at $99 per month for basic features and scales up with add-ons. DecoNetwork runs around $199 and up, depending on how many stores or users you have. YoPrint starts at $69 per month, while PriceIt is $100 per month, with custom pricing depending on the size of your shop. Chipply is free for fundraising and online store campaigns, with the company building its margin into the garment cost. STAHLS’ FulFill Engine is tied to the company’s overall online ecosystem, in which pricing depends on order volume and setup needs.

Understandably, the sticker price of some of these systems might give you pause, especially if you are used to doing things manually. Here’s the reality, though. A good system can easily save five or more admin hours a day. Think about all the time you spend chasing down approvals, copying and pasting order details or repeatedly answering the same customer questions, then think about all that going away. Doing the math, if you value your time at $25 an hour, we’re talking over $2,500 a month in terms of recovered cost ($25/hr x 5 hours per day x 20 days per month = $2,500), that and time that can now be spent selling, improving your production processes or actually taking a day off every now and then.

Bottom line: a strong workflow system does more than just organize your shop. It becomes a foundation for growth. It reduces variables, keeps everyone in the loop and ensures key information is not trapped inside a single person’s (the owner’s) head. That’s the real payoff.

When your systems are running smoothly and your team knows exactly what is happening, the owner becomes less important in terms of the day-to-day. This in turn opens the door to building something that runs with or without you. That’s not just a return on investment—it’s a return on freedom.

The Future of Automation and T-shirt/Apparel Decorating

The automation wave is not slowing down, and artificial intelligence (AI) is riding right alongside it.

What used to feel futuristic is quickly becoming standard. Direct-to-screen systems are dropping in price, modular automation tools are showing up in more entry-level formats, and mobile-friendly dashboards are making it easier to manage production from anywhere. Even smaller shops can now access the kind of tools once reserved for the big guys.

In the next three to five years, expect AI to play a much bigger role in how shops run. We are already seeing AI-powered systems that can prep artwork, suggest ideal print placements and even recommend ink setups based on past jobs and garment types. Some platforms are experimenting with predictive scheduling that adjusts your production calendar automatically based on rush orders and labor availability.

Hybrid production systems are coming too, combining auto screen printing, DTF and embroidery into a streamlined workflow process managed by smart software. As AI integrates deeper into customer relationship management (CRM) and enterprise resource planning (ERP) systems, you will also invariably start seeing tools that suggest upsells, flag high-value customers and track profits in real time—all for less than $500 a month.

That having been said, the very best automation does not start with a machine. It starts with a mindset. Namely, yours.

The shops that are going to thrive with the arrival of the next automation wave are not the ones with the most equipment. They’re going to be the ones that have the most clarity in their goals, the most straightforward production processes, the best-trained people and the confidence (and understanding) to know if and when it’s time to let go of old habits.

Real automation is not about doing more work faster. It is about building a business that works better without you standing in the middle of it. Start small. Start smart. Measure where you are and know where you’re going.

Then automate for that future—not someone else’s.

Marshall Atkinson is a veteran designer, custom apparel decorator, business coach and principal of Atkinson Consulting, (atkinsontshirt.com). This past year he launched the online “Midjourney: Elevating Print Creativity” newsletter, which covers the latest in generative AI (midjourneyexperience.com).

This article was updated on Sept. 30 2025, to reflect new insights for apparel decorators.