For too long, apparel decorators have had to choose between operational chaos and stunted growth. GelatoConnect Apparel is rewriting the economics of production, allowing decorators to double revenue while cutting operational costs by 40%.

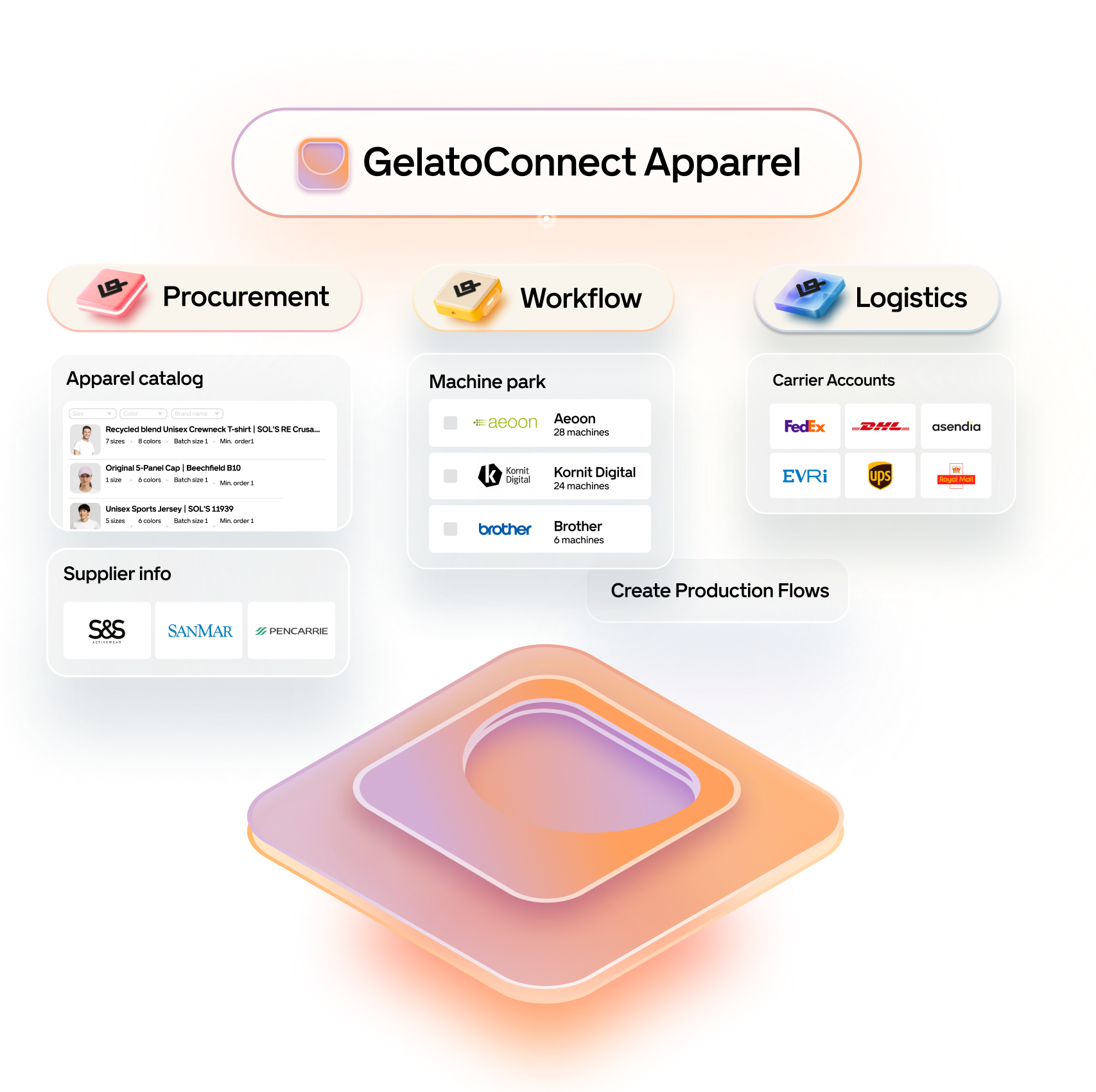

By replacing fragmented tools with a single, intelligent operating system, GelatoConnect links procurement, workflow, logistics, and ecommerce. The result is not just efficiency; it is massive, capital-free scalability.

Real Results, Real Speed

The impact of connecting these operations is immediate. Early adopters are reporting transformative numbers:

WeMust (Canada/US): A major DTF producer hesitant to enter print-on-demand due to operational complexity. GelatoConnect acted as a “crash course” in efficiency. The result? They fulfilled 20,000 orders in their first 30 days and are now quadrupling their DTG capacity.

TidyMerch (Sweden): Achieved 100% year-over-year revenue growth. By automating procurement, they cut deadstock to near zero and slashed shipping costs by 40%.

Imperial Custom Apparel (US): Reduced product listing time from 2 hours to 5 minutes. Using GelatoConnect’s AI-powered Store Link, they now publish 300 products a day, reclaiming hundreds of hours previously lost to manual data entry.

The “Connection” Advantage

“Before GelatoConnect, I had 10× overstock of some SKUs and constant stock-outs of others. Now, I have full visibility – materials move only when needed,” said Charlie Saunders, CEO of TidyMerch. “We’ve reduced deadstock and doubled output without adding cost.”

The transition to profitable on-demand production depends on connection. When storefronts, inventory, and shipping carriers live in separate silos, decorators waste time coordinating instead of producing.

“The creator economy demands variety. Customers want choice, and this industry has the creativity to supply it,” said Rebecca Razulis, COO of Gelato. “But you can’t access that demand if your software doesn’t protect your margins. A connected operating system makes variety profitable.”

How It Works: The New Infrastructure

- Procurement that protects cash flow: Automated tools track inventory in real-time, triggering just-in-time ordering. This frees up working capital previously tied up in piles of blank garments.

- Growth via Store Link: Connect directly to Shopify, Etsy, TikTok Shop, Amazon and B2B platforms like Infigo. AI generates production-ready mockups and listings in minutes, allowing decorators to onboard new brands without increasing overhead.

- Agnostic Workflow: Whether you run Brother, Kornit, or Aeoon, the platform routes orders based on machine availability and specs. The zero-code builder lets you adjust production paths in minutes, not weeks.

- Intelligent Logistics: The system compares rates across 80+ carriers in real-time. This AI-driven selection delivers 25-40% shipping cost reductions and 98%+ on-time dispatch rates.

Global Scale, Local Production

For manufacturers like LUM Studios, this infrastructure is the key to global expansion.

“Our vision is hyper-automated production in every major market we serve — with Atlanta today and Madrid and Paris on the horizon. This is what GelatoConnect enables: mega cities producing what mega cities consume,” said Jaime Borrero, CTO, LUM Studios. “Urban real estate is expensive. You need intelligent systems to control inventory and speed. GelatoConnect gives us that.”

Waste Reduction as a Profit Driver

Sustainability is no longer just a goal; it’s an operational asset. By moving to just-in-time procurement, decorators are eliminating the industry’s biggest cost center: waste.

Read more in Gelato’s report: Zero Deadstock 2026: The Apparel Industry Outlook.