Hirsch Solutions, a leading distributor of embroidery technology in North America, is currently promoting the i-TM (Intelligent Thread Management) feature now available on its Tajima TMEZ embroidery machines.

According to Hirsch, the groundbreaking innovation “marks a significant leap forward in embroidery automation, bringing true digital thread control to shops of all sizes.”

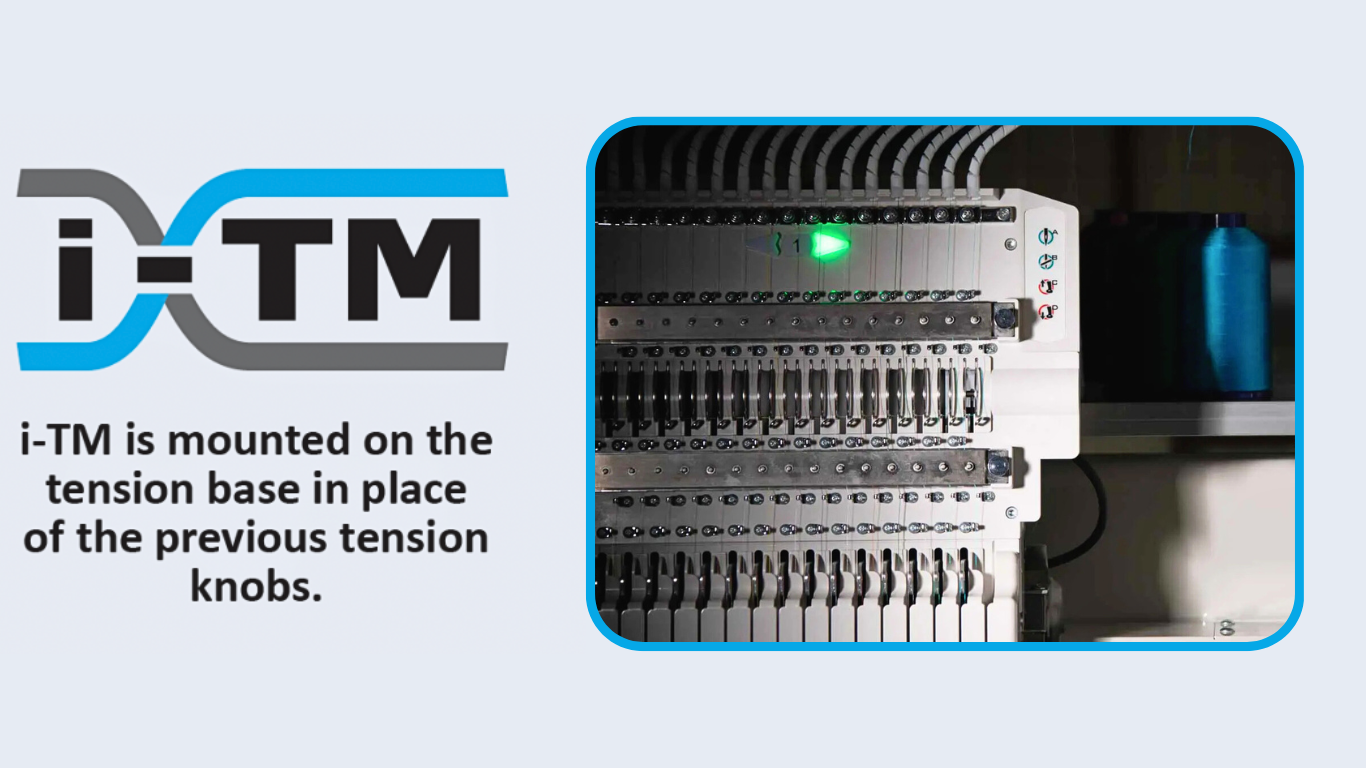

The company goes on to describe the TMEZ line as the first line of embroidery machines in the world to feature i-TM, a smart system that automatically adjusts thread tension based on fabric type, stitch density, and design characteristics—virtually eliminating manual tensioning.

“With i-TM, decorators can focus on creativity and output, not machine settings,” said Ed Levy, VP of Technology at Hirsch Solutions. “We’ve seen this technology transform production floors—cutting setup time, reducing errors, and delivering consistent results across the board.”

Key Features of i-TM system include:

- Automatic Thread Tensioning: No more guesswork. i-TM ensures perfect tension for every design, fabric, and thread—automatically.

- Superior Stitch Quality: Clean, consistent stitches from start to finish, even on complex or layered designs.

- Beginner-Friendly: Removes the learning curve and simplifies operation, making the TMEZ ideal for high-turnover shops and growing businesses.

- Efficiency Gains: Reduce downtime, eliminate test runs, and improve output without sacrificing quality.

For more on the i-TM-equipped TMEZ line and Hirsch Solution’s extensive line of decorating equipment made available via its distribution centers in North Carolina and Arizona, including such top brands as Tajima, Brother, Mimaki, Hotronix and more, click here.