Stepping into commercial embroidery can be a wild adventure—creative, rewarding and sometimes a little daunting. And just like with any new adventure, you must prepare for what’s to come via research, seeking advice and selecting the correct tools. That being said, at the core of every embroidered piece lies one unassuming but essential tool: the embroidery hoop. It might seem simple, but choosing the right hoop can dramatically influence your embroidery’s quality, productivity and profit.

But don’t worry, we’ve brought in top industry professionals to offer their most effective techniques on all things hooping. Let’s dive in!

Why Hoops Matter: Setting the Stage for Quality

What is an embroidery hoop? In a nutshell, embroidery hoops stabilize fabric, keeping it taut and secure during stitching. Without proper hooping, decorators risk puckering, shifting or distorting embroidery designs. Bob Stone, vice president of sales at Barudan, highlights a vital rule, “The size of the hoop in relationship to the size of the design is crucial. Ideally, you want the smallest hoop possible to prevent flagging or puckering of the fabric.”

Scott Stengel, Melco’s master digitizer, encourages decorators to make sure the available hoop sizes allow selection of the smallest hoop possible. “It is very important to do this to achieve the best registration results and to save costs on backing,” he says. “Also, make sure the hoop will hold the garment securely. The very rigid material often used in coats, lunch bags and certain types of leather garments can be poorly suited for traditional hoops. This is due to the fabric not being able to tightly bend between the inner and outer hoop. The last thing you want to happen is for the garment to become ‘unhooped’ or end up with hoop marks aka hoop burn.”

Durability to stand up to the demands of commercial production is another must, says Jaime Tweddle, senior manager at Brother International Corporation. “Not only should it be durable, but the hoop should also possess quick-and-easy machine attachment and removal to facilitate production efficiencies.”

Bottom line: choosing the right hoop size is key to maintaining the fabric’s stability and achieving professional results every time.

Breaking Down Hoop Types: What the Pros Recommend

Let’s look at common hoop styles, their strengths and how they stack up according to the experts.

Round wooden hoops are lightweight, affordable and ideal for at-home businesses. Photo by MarekPhotoDesign.com – stock.adobe.com

Traditional Hoops: Traditional hoops are classics—simple, reliable and adjustable. They can be round, rectangular or square. They’re ideal for everyday embroidery and widely favored for their flexibility. Standard round hoops are the workhorse of many embroidery shops. Made from plastic or wood, they typically come in sizes such as 4 inches, 5.5 inches, 7.5 inches and 12 inches.

Stone emphasizes their versatility but cautions: “Traditional round hoops work fine for most garments, but it takes experience to know how tight or loose to hoop. Too tight causes hoop marks. Too loose risks the garment popping out.”

Stengel agrees on versatility, especially with tricky fabric. “Many times, traditional plastic hoops are best for slippery fabrics like performance wear and nylon satin-type garments. Magnetic hoops can sometimes allow these fabrics to slip, which we obviously don’t want!”

Rectangular & Square Hoops: These hoops provide a bigger embroidery field and are a fantastic fit for when your design is more rectangular in shape. Common sizes include 8-by-12-inches, 11-by-13-inches and 10-by-10-inches.

“Square and rectangular shaped traditional hoops focus extreme tension in the corners of the hoop and sometimes don’t provide stability from slippage along the middle of the hoop areas,” says Stengel. “To avoid this, many times, the square or rectangular hoops can be wrapped with thin foam or hem tape to decrease slippage.”

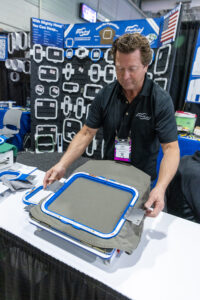

Magnetic Hoops: Magnetic hoops, such as Mighty Hoops, use strong magnets instead of manual tightening, speeding up production dramatically and reducing physical strain.

Complimenting their growing popularity, Tweddle says “specialized hoops like magnetic systems are making hooping faster, easier and more efficient. Having the right tool really boosts efficiency and stitching quality.”

Yet, embroiderers should remain vigilant and use them selectively.

Clamping systems like Melco’s Fast Clamp are perfect for speed and items that can’t be traditionally hooped. Photo courtesy of Melco

“Magnetic hoops have revolutionized embroidery—operators love their ease, and machine owners appreciate their durability,” says Stone. “But magnetic hoops can have a tendency to overstretch thin fabrics, like performance wear, causing registration problems. Magnetic hoops are game changers, but they’re not the solution for every application.”

That said, magnetic hoops benefit beginners and new employees especially. Shops can significantly cut the learning curve for new hires due to ease of use and consistent fabric tension.

Clamping Systems: Clamping systems like Hooptech’s Slim Line or Melco’s Fast Clamp Pro excel at handling difficult-to-hoop items and sensitive materials without leaving marks.

Stengel notes, “Traditional hoops aren’t suitable for leather or velvet—they leave permanent hoop marks. Leather, for example, is not well suited for traditional hoops because it can leave marks. Many times, lightly spraying garments like knit shirts will make hoop marks disappear, but this is not the case with leather and velvet. Once the fabric is damaged by the pressure between the inner and outer hoop it can’t be repaired. Clamps are a much better choice for delicate or thick, rigid materials.”

He also suggests clamps for hard-to-reach embroidery spots. “Another great choice for the ‘how am I going to hoop that?’ question. They allow you to embroider very small or deep areas, such as shirt pockets or bag interiors.”

Cap Frames: Because of the curves and complexity inherent in cap construction, cap embroidery requires specialized framing. Cap frames are designed to hold curved surfaces and often require a cap driver attachment for your machine. Options range from traditional to wide-angle styles for deeper embroidery areas.

Picking the Right Hoop for Each Job

When choosing hoops, consider the following factors shared by the pros: hoop size vs. design size; fabric type and material; and compatibility with the machines you are using.

Hoop Size vs. Design Size: All three experts strongly advise selecting the smallest hoop that comfortably fits each design. According to Stengel the benefits include better registration, less backing waste and improved stitching quality.

Rectangular or square hoops provide a bigger embroidery field to stabilize larger stitch areas. Photo courtesy of Impressions Expo

Tweddle also cautions against extremes when weighing hoop sizes. “Too small hoops slow down operators, making hooping inefficient. Too large hoops waste stabilizer and risk shifting, causing poor stitch quality.”

Fabric Type and Material: Matching hoops with materials is essential. As previously mentioned, rigid fabrics can create issues during the production process.

“Rigid materials like heavy coats, bags or leather often slip out of traditional hoops, making clamps or magnetic hoops necessary,” says Stengel.

Similarly, Stone says magnetic hoops are ideal for thick fabrics like jackets and towels. However, traditional hoops are typically better for performance wear to avoid overstretching.

Machine Compatibility: Ensuring hoop compatibility with embroidery machines avoids costly errors. Hooping systems should ideally be recognized by your machine. “This limits errors, enhances efficiency and prevents expensive repairs,” Tweddle says.

Stone also emphasizes cost-benefit considerations, saying the first thing shop owners should determine is how often the hoop will be used. Will it be for an occasional application? How many different sizes of hoops or clamp windows will be needed? It can be a very large investment to purchase many different sizes.

“Magnetic and clamping hoops aren’t cheap. Shops need to evaluate how often they’ll use these specialty hoops before investing,” he says.

Ultimately, it all comes down to choosing the right hoop for the job. According to Tweddle, whether it is a traditional, magnetic or clamp style hoop, choose the system that works best and allows for the best fit for efficiency and stitching results.

Common Hooping Challenges and Expert Solutions

Even after compiling the proper research and equipping your shop with the correct hoops, issues can still arise as all production jobs differ in varying degrees. Luckily, while you’re bound to run into the following common hooping headaches, solutions exist as well.

Operator Fatigue: Operator strain from repetitive hooping tasks can be a problem for larger shops especially, due to their use of multi-head machines and high volumes. “Most of the time this means the operators are constantly hooping items for hours at a time,” says Stone. “This can lead to hand and wrist injuries or, worse, carpal tunnel syndrome. [However,] the use of hooping stations, magnetic hoops when possible, clamps and pneumatic hooping devices can help eliminate operator injuries.”

Efficiency and Workflow: Many shops have too few hooping stations, which can lead to inefficiencies. Throughput can easily be increased by purchasing more of them. Another common shortfall, Stengel says, is due to hoops and supplies being located too far away from the hooping areas. Facilities must arrange stored hoops, thread and backing close to these stations.

“Too much time can be wasted walking around and away from the hooping area to acquire thread and backing for on-deck orders,” Stengel says. “We also commonly see [shops where] there are not enough hat hooping stations on the production floors. Many facilities benefit greatly by adding more than one hat hooping station per embroidery machine pod. This eliminates a common production bottleneck.”

Improper Training: Unsurprisingly, the biggest challenge is making sure all operators have the necessary training to properly use the correct hoop for each job. Adding another layer, seeking professional assistance for choosing the correct hoop and accessories for each type of embroidery jobs ensures the correct setup for your business. “Brother’s dealer network can be key to providing this type of assistance,” says Tweddle. “Choosing the wrong mix of hoops and accessories can cause loss of productivity, poor stitching results, wastage due to improper setup and use, and potential damage to the machine and or accessory.”

Looking Ahead: The Role of Technology and ERP Systems

Many may wonder what an enterprise-resource-planning (ERP) system has to do with hooping. However, being software that acts as a kind of central nervous system to help a company keep its core business processes all in one place, it can be critical. Specifically, an embroidery-focused ERP system can play a significant supporting role in managing hoop usage by streamlining job scheduling, equipment tracking and production planning. It can even automatically assign the correct hoop size based on design dimensions and garment type, minimizing setup errors and reducing downtime. For shops with limited hoop inventory, the system can also track availability and prevent scheduling conflicts.

Cap frames are designed to hold curved surfaces and often require a cap driver attachment. Photo courtesy of Impressions Expo

“ERP systems are becoming invaluable to larger embroidery companies,” Stone says. “Not only can they improve workflow by networking to the embroidery machines, but they can also alert the operator to the size and type of hoop to use along with placement on the garment. This speeds up the embroidery process and reduces mistakes.”

ERP software also stores standardized hooping instructions, ensuring consistency across operators and shifts. By analyzing production data—like hoop usage trends and setup times—an ERP system empowers embroidery businesses to optimize workflows, train staff more effectively, and maintain high-quality output with greater efficiency.

Stengel envisions a near-future in which embroidery management software guides embroidery jobs dynamically. “In the not-too-distant future production management software will know what thread is on which machine and active hoops. This will direct orders to the machines with the least amount of changeover time.”

That having been said, Tweddle encourages a measured rollout when introducing this kind of new technology into your shop.

“These software and ERP workflow tools can help a business better organize their business to ensure their processes, inventory and operations are aligned to maximize productivity,” he says. “However, the ability to make quick changes, positioning, sizing and job enhancement right on the machine can also be key to a productive environment. Depending on the size of the business operation, introducing too much software too early can be counterproductive. Shops should carefully time these integrations based on their growth.”

Expect to see more embroidery businesses using ERP software to take the guesswork out of hoop management.

Building Your Ideal Embroidery Setup

Whether you’re just starting out or have years of embroidery experience, using the right hoops for your machine is essential for producing clean results and maintaining a streamlined workflow. Reputable brands offer durable, versatile solutions that can be tailored to fit your shop’s needs.

Selecting hoops isn’t solely about dimensions—it’s a fundamental part of optimizing your production process. A thoughtful setup can help reduce errors, limit downtime and improve consistency across all orders. From traditional options to advanced magnetic and clamping systems, understanding what’s available ensures your operation runs smoothly from the first stitch to the final product.

As Tweddle puts it, “Having the right tools and professional advice at every step ensures your embroidery business achieves maximum efficiency, quality and profitability.”