The functionality and versatility of today’s heat presses have evolved, but they all should be safe, reliable and consistent, a sentiment agreed upon by many industry experts.

One major factor in the increasing versatility of this staple garment-decorating machine is the wide assortment of available platens. “The Insta 256 manual swing-away heat press comes with a standard 16″ x 20″ lower platen that works great with large-sized graphics,” says Kelly P. Smith, executive director of sales and marketing for Insta Graphic Systems. “Also available is a 6″ x 6″ platen for neck and chest transfers; a 6″ x 15″ platen for sleeves and pant legs; a 10″ x 15″ platen for children’s garments; and a shoe platen.”

Josh Ellsworth, senior vice president, dealer and enterprise sales, Stahls’, says today’s heat presses are “smarter,” have been designed for manufacturing operations, and include features such as cloud-based platforms that can report various production analytics. “This helps a business manage its workflow, identify application errors and track staff efficiency,” he says.

The company’s Dual Air Fusion heat press allows apparel decorators to print more items with more accuracy and efficiency, thanks to two heat-printing stations that can be calibrated to different time, temperature and pressure settings. It also features a large, high-resolution touchscreen with a stylus pen.

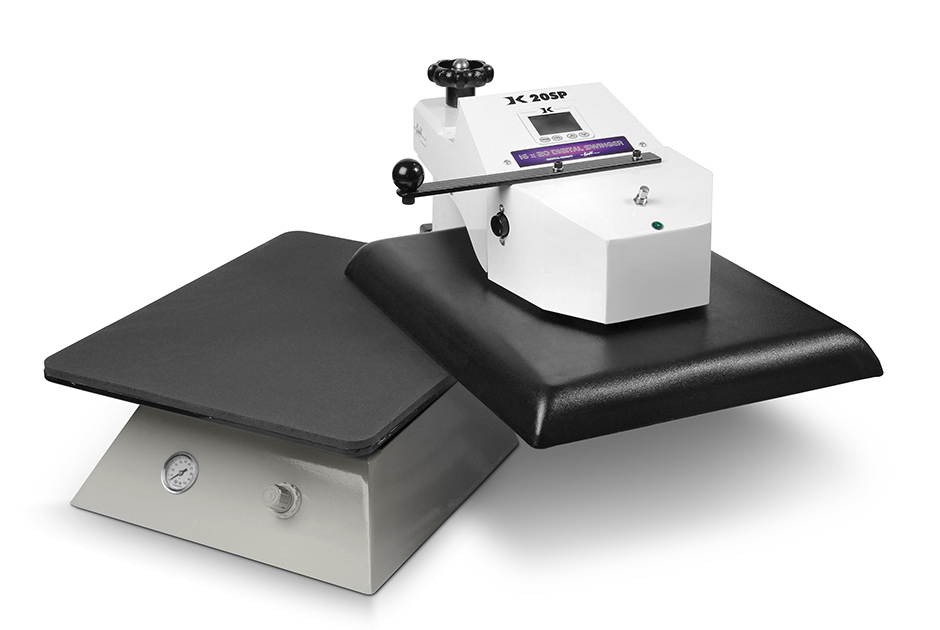

Aaron Knight, vice president, Geo Knight & Co. Inc., credits the addition of fully, separately, digitally controlled bottom heat attachments with the increased popularity of the company’s DK20SP heat press.

“Bottom heat allows for better adhesion results with zero press marks or stamp marks on sensitive applications,” he says. “Improvements to the controller and additional features also allow for more options in production. The open-ended design of the instantly interchangeable bottom tables allows for custom customer pallets and tables to be provided quickly to accommodate special products.”

Ellsworth agrees that heated lower platens are more prevalent in today’s heat presses. This function, he says, has been proven to alleviate scorch marks on the face of heat-sensitive fabrics.

Henri Coëme, global sales manager, graphic imaging for HIX Corp., says the company has upgraded and adapted its presses by adding more features that can accommodate different applications.

“The company has always created a variety of presses, both clamshell and swing-away, to respond to as many of its customers’ demands as possible, without needing to pay for unnecessary features,” he says.

Ideal Features

Features of an ideal heat press differ for everyone. Knight says it’s important to find a model with consistency and versatility.

“[The DK20SP] is 16″ x 20″, fully push-button automatic in operation and extremely versatile for many applications,” he says. “The primary benefit is the consistency of an automatic [heat] press.”

Knight says the DK20SP easily can withstand multiple decades of heavy use because of heavy-duty, unbreakable construction. He says the digital controls and programmable presets are easy to use and efficient, and an adjustable height for up to 2-inch-thick materials allow for a variety of non-standard products to be pressed.

Coëme says the ideal heat press should perform multiple applications. “If applying standard plastisol transfers, I would prefer a clamshell press with digital temperature, time and pressure readout,” he says. “If working with sublimation transfers, I would like to be able to split the shirt over the lower platen, so that the gaseous ink doesn’t migrate to the back of the shirt. Since sublimations transfers also take a little longer, I value a timing mechanism that opens the press at the end of the cycle.”

Smith describes Insta Graphics’ 256 manual swing-away heat press as a professional-grade machine that features heavy-duty heat and pressure distribution across the entire platen. For direct-to-garment (DTG) printing applications, Coëme says an auto-open feature guarantees minimal compression time and the best possible hand.

Ellsworth says the Hotronix Dual Air Fusion excels in DTG workflow because of its auto-regulated air pressure that is controlled via the touchscreen display. “This allows an operator to toggle between heavy and light pressure without having to maneuver a pressure-adjustment knob,” he says.

Regarding sublimation applications, bottom heat is a difference maker. “In the sublimation world, I want the option of bottom heat for a press to [be able to] decorate both sides at same time,” says David Gross, president of Condé Systems. “It is a pain to press one side, flip the item and press [the] other side. When you don’t need bottom [heat], you can remove it. Time is money, so we love presses that are versatile and can accept bottom heat.”

Ellsworth says sublimation decorators should prioritize a heat press that can accommodate thicker items and locks down evenly, which discourages “ghosting” due to sublimation paper shifting during application. “It’s a common misnomer that only a swing-away heat press is capable of this application,” he says. “Some clamshell machines, like those manufactured by Stahls’, have a patented upper floating platen that is perfectly capable of completing quality sublimation results.”

When it comes to heat-applied graphics, Knight says pressure is key. “The DK20SP is capable of generating 3,000 pounds of total applied force at 100 psi with its maintenance-free, self-leveling airbag system,” he says. “Transfers need uniform and very firm pressure, and the DK20SP is the most reliable in that department.”

Smith adds that for decorators applying transfers in large volumes, automatic heat presses improve productivity and reduce operator fatigue. “The Insta 728 has been technically designed to produce and evenly distribute controlled pressure throughout its platens for reliable results with every transfer application.”

Buyer Beware

Knowing what to look for in a heat press is important but knowing what to avoid also is helpful. When you see warning signs or red flags, beware of investing in a questionable heat press.

Knight says you can learn a lot just by visiting a supplier’s website. A lack of information for customer support, or an unclear or unposted manufacturer name and address are telltale signs.

“A reputation for long-lasting, reliable equipment and same-day support will be easy to find,” he says. “Try contacting the manufacturer and asking a few quick questions, and you will know what type of company you will have backing your business and keeping you profitable.”

Ellsworth says performance consistency is important because aesthetics can be deceiving, but what’s under the top heater is critical. “Many inexpensive presses are made with very thin upper heat platens, which do not retain heat when completing even a 30-piece job,” he says. “This heat loss causes temperature inaccuracy and application failure.”

Smith points to price as an indicator. “If the purchase price of a heat press is very low and seems too good to be true, be very cautious and try to understand why,” she says. “There are reasons quality heat press machines cost more than the low-cost ‘disposable’ machines available from some online manufacturers.”

Ellsworth says buyers should beware of heat presses that have a drawer handle with a clamshell design. “Currently, no [United States] manufacturer makes this style of machine, so they have a high likelihood of delivering inaccurate results.”

Smith advises buyers to consider durability, reliability, technical support, parts availability, warranty, and even pressure and temperature across the entire platen.

The ‘Eyeball Test’

Ellsworth says there may not be an eyeball test to help determine whether a heat press is substandard, but buyers should look for at least one thing to signal quality.

“Look for ‘Made in the USA’ and you can at least count on the fact that you are buying a quality machine,” he says.

Smith says images of heat presses available online can be deceiving. “Photoshop can do wonders, so if the brand is not recognized for producing quality machines, this will be the first clue the machine is substandard.”

Gross agrees. “When you pay very little for something that you plug in the wall that uses a lot of power, gets hot, etc., understand that by paying very little, it is perceivable that somebody has cut corners,” he says. “If the deal looks too good to believe, there’s probably a reason why.”

Jennifer Morrell is an award-winning writer who has written for a number of national consumer and trade publications. For more information or to comment on this article, email Jennifer at [email protected].