In today’s uncertain economic climate, staying successful in business means diversifying your company’s offerings as much as possible. And also that means finding a niche that sets your shop apart from the competition. Whether it is printing in unique locations or on interesting garment choices, there’s a pallet for practically anything or any location you want to print on.

Here’s five specialty application pallets that will enable you to accomplish these goals quickly and easily. They were designed specifically for most models of screen printing presses, or Kornit or Epson digital DTG presses.

Face Mask Pallets

Challenge: Face masks were perhaps the first salvation for struggling printers when the pandemic hit and the decorated apparel business took a sharp decline as schools, restaurants, entertainment venues, fundraisers and a host of other companies and functions temporarily shut down or closed and the demand for T-shirts seemingly dried up overnight. Savvy printers saw the immediate need for face masks first for front-line responders and then consumers who would be mandated in many states to wear them any time outdoors and into private businesses.

The issue became how to get the small, multi-layered substrate pulled tight enough on a screen-printing press or DTG machine to print on the small area. This was especially true of form-fitted face masks with the elastic hems, puckering on the sides, and often a seam down the middle. Enter the face mask pallet, a small attachment that holds form-fitted or flat face masks in place.

Printing Solution: The holddown pallet basically pulls the mask flat and tight, leaving the small part of the mask to be printed exposed. A quick pull of the squeegee, release the pallet, and you have a nice, clean print that’s ready for the dryer or heat gun. Face mask pallets come in single-, dual- and four-mask models, which make production printing faster and easier.

Zipper Hoodie Pallet

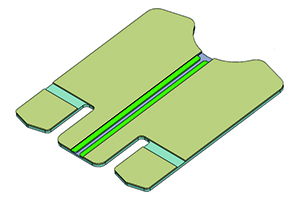

Challenge: Zipper hoodies remain one of the most popular garments for apparel printing due to warmer climates and the fashion detailing the manufacturers are designing these days. The array of choices seems endless, with new styles coming out every season and enjoying a longer life as the hoodie replaces a traditional heavier jacket or coat. The problem is…the zipper rises off the pallet. In addition to compromising your print, it can destroy your screens over time. How do you get a smooth, even print across the hemmed seam assembly of a zipper hoodie over the zipper itself without the print being lopsided or out of registration?

Printing Solution: The zipper hoodie pallet is uniquely designed with a groove machined vertically down the middle of the pallet, creating a two-tiered slot for the zipper to drop down into. It also is designed with load side geometry for accurate loading. This allows the garment to be pulled tight so the hemmed seams meet in the middle, providing an even printing surface that allows you to print all the way up to the shoulder seam and the hoodie/neck seam. A screen or DTG press operator can effortlessly print across the zipper portion of the hoodie and achieve a design that crosses the middle of the garment’s split seamlessly.

Double-Sleeve Pallet

Challenge: The pallet bracket or arm of the machine is too big to fit the sleeve of a garment over.

Printing Solution: This lightweight pallet is designed to fit sleeves without stretching the garment when pulling it tight for printing. By loading the garment through the neck area down to the cuff, you can print a portion of or the entire sleeve. This versatile pallet, made of high-strength aluminum, is designed with the middle of the pallet eliminated. This allows for the squeegee to follow the pallet as the pallet deflects down so you get normalized print density even on the outside of the pallet. A double-sleeve pallet can print two sleeves at once, speeding production. This pallet also can be used for custom printing on socks, pockets, Koozies, pant legs, short sleeves, gloves and more.

Combination Pallet

Challenge: How do budget-constrained screen printers save shelf space, production time and costs?

Printing Solution: A versatile combination pallet allows you to print on pockets, tagless, zipper hoodies and more. One side of the pallet allows you to print zipper hoodies all the way up to the shoulder seam and over the entire printable area of the hoodie. Take the pallet off and spin it around, and you’re able to print either two pockets at the same time or print two inside neck labels at the same time. This pallet combines three top printing solutions into one compact, easy-to-use and cost-effective design.

Two-Ply Holddown

Challenge: Athletic shorts, reversible mesh jerseys and nylon jackets are made of multiple layers of material, making holding them down for printing a challenge. While an adhesive is used to hold down the bottom layer, the top layer can slip during the printing process.

Printing Solution: The standard way of securing material to a pallet during multicolor printing is to use adhesive on the pallet surface. However, with multiple layers of fabric, this method will not hold the garment securely in place during printing. So you must use a holddown pallet that secures all layers in place. This pallet has a built on spring-assist head frame that grabs all four sides of the garment and pulls tightly in all four directions. The result is a completely flat and tight printing surface that won’t move during printing. The custom-designed spring clamp locks the pallet down in one easy motion, keeping the jacket pulled tight and providing the correct amount of tension. This ensures that you get the best ink penetration on the garment so the colors look good and last longer.

Screen or digital printing on unique placement areas of a garment or on a distinct garment doesn’t have to be a challenge that holds you back from becoming known as that decorator in town who sets itself apart and wins the business in this very competitive marketplace. If business is a bit slow because of the economic conditions in your region with the pandemic affecting things, now’s the time to experiment with different printing applications. Then, gear up for the certain-to-be upcoming boon the decorated apparel and promotional products industry will experience as the pandemic subsides and the world adjusts to a “next” normal.

Erik Naftal is the owner and president of Action Engineering, Atlanta, Georgia, USA, a company that manufactures specialty application pallets for screen and digital printing, as well as squeegees, floodbars and other printing accessories. To comment on this article or contact Erik, email [email protected] or visit actionengineering.com.