Within the screen-printing industry, the spotlight usually shines brightest on the vivid inks, intricate designs, and crisp apparel. But behind the scenes—quietly sliding across every screen—is a humble yet mighty hero: the squeegee. Sure, it might not grab attention like the artwork it helps create, but every seasoned screen printer knows that this simple tool is essential to a successful print run. From shaping color vibrancy to defining edge sharpness, it’s the silent champion ensuring each garment leaves your press looking its best.

Whether you’re new to the craft or a seasoned pro, understanding how to select, use, and care for this trusted tool will lead to smoother operations, happier customers, and consistently stellar results.

Screen Printing Lessons Learned

Early on, my father, Gary Sr.—a master carpenter—taught me to “take care of your tools and keep them organized,” not just for the sake of order, but to save time and eliminate waste. That advice has stayed with me for decades. I’ve spent countless hours analyzing the tools and techniques that drive print quality and consistency. And one of the most important—yet often overlooked—is the squeegee.

Let’s break down the components that make this tool so vital: type, blade profile, hardness, and construction. Understanding these elements—and investing in a broader squeegee selection—can have a profound impact on your bottom line. Just as a mechanic wouldn’t work with only one wrench, your print operators shouldn’t rely on just one squeegee.

A side-by-side comparison of manual wooden-handled squeegees and automated aluminum-handled squeegees. Photo courtesy of International Coatings

Squeegee Basics: Understanding the Tool

A squeegee is more than a blade on a handle. It’s the bridge between your screen and substrate, controlling how ink transfers onto your garment.

Components include:

- Blade – Made of polyurethane, available in various hardness levels and shapes.

- Handle – Wood, aluminum, or ergonomic.

- Mounting system – Varies between manual and automatic presses.

Durometer: The Power of Flexibility

Durometer measures blade hardness (Shore A scale) and determines blade flexibility. Each level impacts ink deposit and detail differently:

- 60 durometer (soft): Deposits more ink; ideal for fleece and specialty inks.

- 70 durometer (medium): The industry workhorse for everyday use.

- 80 durometer (hard): Ideal for halftones and fine detail.

- Triple durometer (e.g., 70/90/70): A hybrid option offering both control and flexibility—especially useful for fast-paced, high-detail work.

Blade Profiles: Choose Your Edge Wisely

Each blade edge serves a different function:

- Square edge: Best for general textile work; offers balanced flow and definition.

- Rounded edge: Delivers thicker deposits; less precision.

- Beveled edge: Designed for printing on uneven or curved surfaces.

- Pro Tip: A worn blade will compromise your print. Dull edges can smear ink and distort lines. Replace or sharpen blades regularly.

Technique Matters

Proper handling enhances every squeegee’s potential:

- Angle: A steep angle provides greater control; a shallow angle increases ink flow.

- Pressure: More pressure flattens the blade, thinning the ink deposit.

- Speed: Fast strokes lay down less ink; slower strokes increase deposit but can blur details.

Remember: Changing the durometer or blade type? Adjust pressure and angle accordingly.

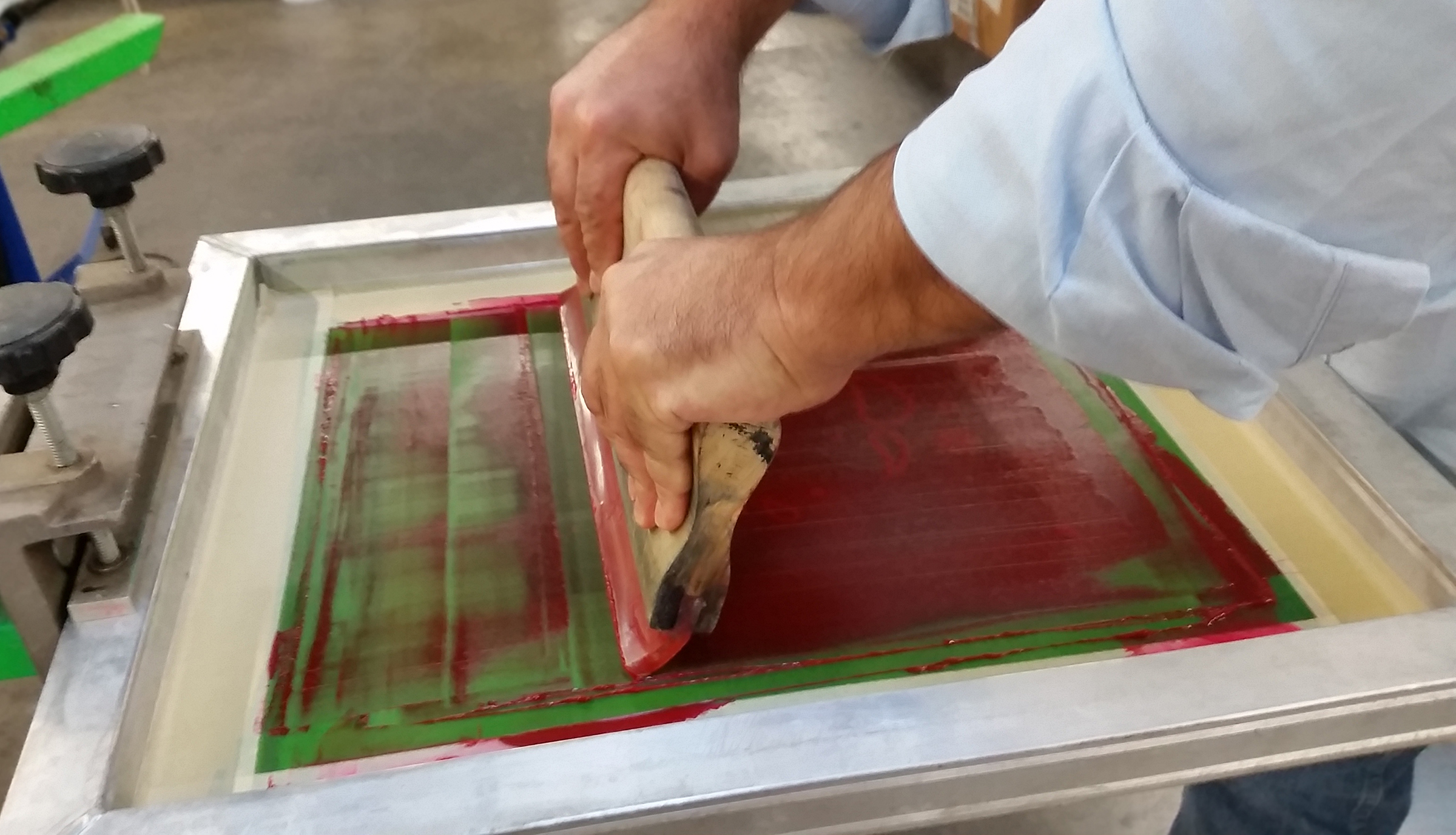

A close-up view of squeegee blades thickly coated with ink. Don’t overlook the importance of proper cleaning to maintain print quality. Photo courtesy of International Coatings

Matching the Squeegee to the Job

Tailor your tool to the task:

- Garment type: Thick materials (like fleece) call for softer blades.

- Ink type: Water-based inks benefit from flexible blades; plastisol works with a range of durometers.

- Design detail: Opt for harder blades and sharp edges for intricate graphics and halftones.

Squeegee Maintenance & Longevity

Your squeegee won’t last forever—but proper care extends its life and performance:

- Sharpen blades regularly.

- Replace blades when you notice nicks or permanent bends.

- Clean thoroughly after each use—avoid harsh chemicals.

- Store flat, away from heat, UV exposure, or ink contamination.

Common Mistakes to Avoid

- Using the same blade for every job.

- Ignoring blade wear.

- Failing to adjust pressure or angle with new blades.

- Under-equipping staff.

- Storing blades improperly.

Equip for Profit

Consistency is the cornerstone of success in screen printing. You can’t produce consistent results with inconsistent tools. By investing in the right squeegee selection, mastering technique, and maintaining your blades, you’ll increase print quality, press speed, and profitability.

A clean, sharp squeegee blade lays the groundwork for crisp, vibrant designs. Respect the blade. Choose wisely. Keep it sharp—and your prints (and customers) will thank you.

Kieth Stevens is the Western Regional Sales Manager for International Coatings. A veteran screen printer of more than 42 years, he is a regular contributor to International Coatings’ blog and the winner of SGIA’s 2014 Golden Image Award. Reach him at [email protected] or visit iccink.com.