August 9, 2016

While the classic aesthetic of embroidery has traditionally dominated the customized headwear market, there still remains a significant place in the hat-decoration business for screen printing. This is especially true when it comes to local sports teams, souvenir shops and promotional items.

As with apparel, remember that finer artwork detail can be achieved on hats via screen printing instead of embroidery. However, headwear — notably baseball caps and trucker hats — offer unique challenges, which we’ll discuss here.

We’ll also examine the requirements for creating designs that are appropriate for the smaller — and often-irregular — surface of a cap’s crown.

The Cap Itself

One of the biggest perceived hurdles to cap customization is the general difficulty of screen printing on the product. Screen printing usually is perceived as a less-desirable form of hat embellishment because of the special equipment required. But after investing in platens for flat-hat printing or a curved hat-printing machine, this aspect of customization simply involves committing to a subset of skills that is not entirely different from screen printing on other garments.

Another hurdle screen printers frequently face is printing over the center seam on the front and back of six-panel baseball caps. But the popularity of trucker hats makes this much less of an issue. In fact, trucker hats — with their smooth, unseamed foam-front panels — provide a welcome canvas for screen printing. This, combined with their generally attractive price points, has made them go-to promotional items.

Regardless of your experience level, you’ve likely discovered that screen printing is a skill and art, requiring mastery of a broad set of variables. When you add factors such as limited size, three dimensions and the stubborn center seams found on many baseball hats, you have an entirely new set of challenges.

However, once you overcome a hat’s unique obstacles, you’re left with many of the same challenges common to screen printing on T-shirts, jackets or sweat shirts.

Using an Underbase

As with all dark garments, multicolor screen printing on a dark baseball or trucker hat necessitates the use of high-opacity inks made for printing on dark colors, or an underbase. This is a flood layer — generally white or another light color — that is used as a base or primer onto which the design’s other colors will be printed.

As with high-opacity ink, the underbase should be flash cured before any other colors are printed over it. This way, the underbase will be properly sealed and the darker surface will not show through

the artwork.

Regardless of the ink’s opacity, you often will apply the underbase twice — flashing it both times — to create a properly opaque background for your designs. Only by applying the ink twice can you be assured that you’ve adequately covered the cap’s fibers so that you do not see the dark-colored fabric underneath.

While you could conceivably print each layer of the design’s color with high-

opacity ink, your results would be less bright and wouldn’t feel as soft without the underbase. This is because the underbase allows you to use lower-count mesh on the base levels of the design, while using higher-count meshes above for a softer overall texture.

Using a white underbase requires an extra screen. The secret for most designs is to slightly choke the art so the white doesn’t peek out from under the color if there is a shift in registration. While it seems intuitive to simply cover the entire design with the underbase coat, the white layer would be visible without proper choking as the layers build up over the underbase.

Choking doesn’t mean reducing the size of the original image; it means making the design’s outline a tad thinner or skinnier. By doing this, the top color will appear bright and opaque when it covers the underbase and simply fade unnoticeably into the dark background on the edges, thus creating the illusion of a perfect border. The best underbase is one you can’t see when you’ve finished printing.

Once your underbase is dry, print all additional colors on top as you would with any other screen-printing job. Just know that the more colors you print, the harder it will be to get a quality design without also flashing at least one or two more times. Otherwise, with too many coats, layers of color may start to buckle and peel.

Artwork Requirements

Creating suitable artwork for hats is more challenging than doing so for T-shirts, not only due to the limited available space, but also because the curved surface can create distortions.

If you’re working with a design that uses shapes, particularly circles, it’s best to consult your graphic designer to ensure it translates properly onto a curved surface. Otherwise, your circles will print as ovals.

Next, get to know the general guidelines for screen printing on most baseball and trucker hats:

1. Designs should be no more than 5″ x 2.5″ for foam-front trucker hats (5 inches wide and 2.5 inches tall). If you’re working on a lower-profile baseball hat, reduce the artwork size accordingly.

2. Lettering must be at least 10-12 point size and converted to a shape instead of a font.

3. All lines must be at least 1 point thick.

Finally, remember to choose the design positioning carefully, especially if you want to offer printing on the front panel of a six-panel baseball cap. A poorly placed design can look disturbing if it is out of balance with the front seam.

Brian Burr is chief operating officer of wholesalehats.com, which has produced embroidered garments for clientele that includes Google, NASA and the United States Army. He has been involved in every aspect of the embroidery industry for more than 20 years, including machine operation and repair. For more information or to comment on this article, email Brian at brian@wholesalehats.co

March 20, 2024 | Production

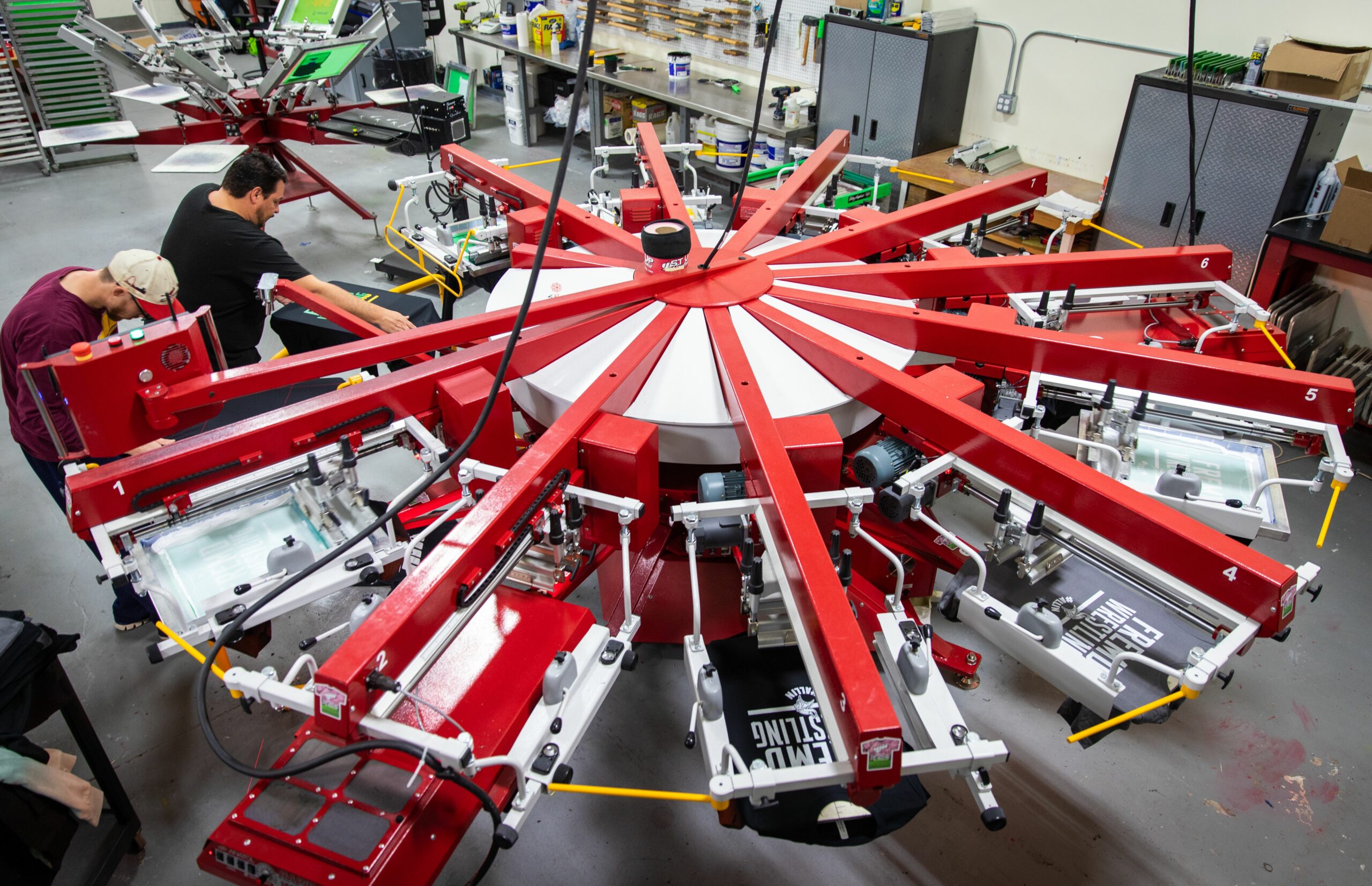

As with pretty much any business, one of the keys for apparel and T-shirt decorators running a successful custom screen-printing shop is having the right equipment, first and foremost, the right press, or presses.

FULL STORY

March 15, 2024 | Production

As is the case with flash units and dryers, screen exposure units, computer-to-screen-systems and washout booths are critical to successful screen printing of T-shirts and other apparel

FULL STORY

January 16, 2024 | Production

Go to any industry trade show or visit an actual custom apparel screen-printing shop, and your eyes will naturally be drawn to the press, or presses there. This is true whether the shop in question employs a single manual press or is running multiple autos.

FULL STORY